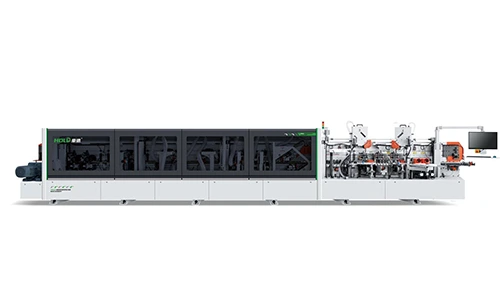

Automatic High-Speed Edge Banding Machine :HQ533J

Feature:

●Heavy Duty Frame: one-piece guide rail, annealed and machined. The rails are mounted on the entire coherent one-piece rail base with no intermediate overhangs for exceptional stability.

●Heavy Duty extra Height Press Beam:comparing with the ordinary press beam, it greatly increases the rigidity and strength, which ensures the stability of the press beam in high intensity operation.

●V-beltfeeding:Smooth workpiece with no indentation for perfect adhesion.

●Two seats and three motors drove fast end-cutting.

●Pneumatic two-stage rough trimming: can be set up for two different thicknesses of the edge band, for a thick and a thin edge band easy one-key switch, to solve the trouble of adjusting the blade.

●For the advanced customization door panel, two groups of edge scraping R1 and R2 are specially designed, with digital display visual reader. For the edge banding strips with differentthickness,with one key easy switch, so as to perfectly remove the knife marks left by the edge trimming and refine the R fillet.

●Edge scraping 2 with laminating function for laminating boards, can be quickly switched to laminating function with one key.

●Two sets of polishing (electric reciprocating + pneumatic dodging).

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Technical parameter

|

Lifting |

CNC Lifting |

|

Feeding speed |

20m-23m-26m/min |

|

Edge thickness |

0.4-3mm |

|

Minimum sheet size |

120x80mm(long edge banding available for 50*300mm) |

|

Sheet thickness |

10-60mm |

|

Working air pressure |

0.6Mpa |

detail pictures

V-belt feeding

Quick melt device + double glue system

Glue removal by six-wheel pressing

Pre-miling

Two seats and three motors drove fast end-cutting

Four-blade high-speed corner rounding

Scraping

Wire breaking mechanism + flexible flat scraping + cleaning agent device

Rubber-coated auxiliary tugs

Product video

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Our woodworking machinery factory values innovation, quality, and sustainability. We foster a collaborative and inclusive workplace, prioritize continuous learning, and commit to environmental responsibility.

Contact: Hanna

Tel: +86 18029386958

Email: hanna@fshold.com

WhatsApp: +86 18029386958

Company Address: Lianfu Road 1 , Fuan Industrial Zone, Leliu Town, Shunde District, Foshan , Guangdong, China

Copyright © 2025 HOLD-www.holdmac.com |Sitemap Privacy Policy