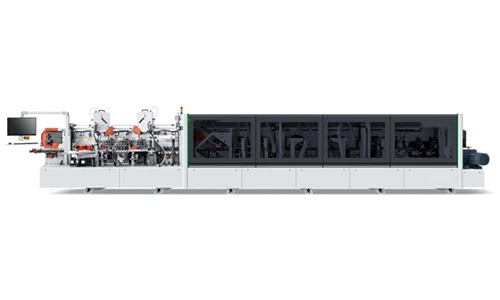

Fully Automatic High-Speed Edge Bander: HQ533JA6A6F

- Left-hand feed.

- Heavy-duty machine frame: Ultra-heavy-duty, featuring an integrated guide rail base that undergoes annealing and machining. The guide rail is mounted on a continuous, monolithic base with no unsupported sections, ensuring high stability.

- Heavy-duty heightened press beam: Compared to standard pressure beams, the heightened design significantly enhances rigidity and strength, guaranteeing stability during high rigidity operation.

- Fully Intelligent Control System: Features fifteen powerful functions, real-time data transmission for immediate equipment status monitoring, and one-click generation of Production reports.

- Top Presser by V-belt: Ensures smooth, indentation-free workpiece pressing for superior bonding results.

- Dual Upper Gluing Systems + Dual 5-post pressure rollers: Each glue pot is available with independent operation or simultaneous use. Compatible with both EVA and PUR adhesives.

- Two sets of six-channel belt conveyors are available with six types of edge banding (maximum width 60mm). Each banding type is available with a freely change over function, reducing changeover time and effectively boosting production capacity.

- Rough trimming + pneumatic two-stage trimming. Available with two different thicknesses of edge banding. Easily change over between thick and thin banding with one button, eliminating blade adjustment hassles.

- For high-end custom door panels, specially designed two scraping units with visual readout. Effortlessly change over between thick and thin edge banding with one button, perfectly removing trimming knife marks and achieving precise R-radius finishing.

- The reducer is equipped with a high-efficiency hard-tooth-surface gearbox for robust performance.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Process

|

Technical parameter |

|

|

Lifting |

CNC lift |

|

Total power |

About 30kw |

|

Overall Dimensions |

About 10700x1000x1800mm |

|

Feed Rate |

20-23-26m/min |

|

Edge Band Thickness |

0.4-3mm |

|

Board Thickness |

9-60mm |

|

Operating Pressure |

0.6Mpa |

|

Minimum Board Size |

120X80mm |

detail pictures

Heavy-duty machine frame + Heavy-duty heightened press beams

Fully Intelligent Control System

Separation Agent Device

Pre-Milling

Board Heating Unit

Gluing System 1 : Fast-Melter + Upper Glue Pot System

Two sets of six-channel belt conveyors

Pressing

Two-Seat Three-Motor Quick end cutting

Rough trimming+ Pneumatic fine trimming for two kinds of edgeband thickness

Integrated High-Speed Four-Blade Corner rounding

Two Sets of Scraping

Wire Breakage Mechanism + Flexible Flat Scraper + Cleaning Agent Device

Deceleration motor

Auxiliary Support Rollers

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Our woodworking machinery factory values innovation, quality, and sustainability. We foster a collaborative and inclusive workplace, prioritize continuous learning, and commit to environmental responsibility.

Contact: Hanna

Tel: +86 18029386958

Email: hanna@fshold.com

WhatsApp: +86 18029386958

Company Address: Lianfu Road 1 , Fuan Industrial Zone, Leliu Town, Shunde District, Foshan , Guangdong, China

Copyright © 2025 HOLD-www.holdmac.com |Sitemap Privacy Policy