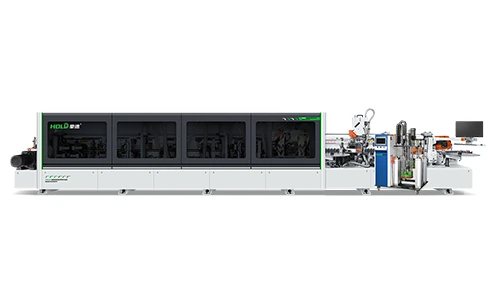

Automatic High-Speed Edge Banding Machine :HD855J

Narrow Edge Banding Machine

lMinimum board size: 150×40mm (four-side edge banding with tracking), 120×40mm (long-side edge banding).

lSpecially designed pre-milling mechanism for narrow end heads of workpieces, capable of milling narrow board end heads of ≥40mm.

lThe frame adopts a heavy-duty structure, processed by CNC to ensure the flatness of the table.

lThe distance between two sets of guide rail columns is densified, ensuring smoother board transportation and better edge scraping effect.

lIndependent motor control for glue application and edge pressing to avoid the case of "less glue at the beginning and more glue at the end" of panels.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Technical parameter

|

Lifting |

Electric lifting |

| Feed speed | 14m-20m-23m/min |

| Edge thickness | 0.4-3mm |

| Sheet thickness | 10-60mm |

| Processing speed | 16m-20m-23m/min |

| Minimum sheet size | 150×40mm (four-sided edge banding, with tracking capability) 120×40mm (edge banding on the long side) |

| Tracking speed | ≤23m/min(narrow board tracking speed14m/min) |

| Board length | ≥120mm (with tracking ≥150mm) |

| Board width | ≥40mm |

| Working air pressure | 0.6Mpa |

| Total Power | 33kw |

| Weight | About 4000KG |

| Equipment dimensions | About 10450x1000x1800mm |

detail pictures

Narrow Board Automatic Side Pressure Device

Wire Breakage Mechanism + Flexible Edge Scraper + Cleaning Agent Device

Two Sets of Edge Scraping

Two rails three motors end cutting

PUR Non-Cleaning Glue Pot + Dual PUR Glue Machine

Hot Melt Adhesive Application System + Rapid Melting + Automatic Glue Extraction Machine

Four-Blade High-Speed Corner Rounding

Five-Roller Pressing

Product video

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Our woodworking machinery factory values innovation, quality, and sustainability. We foster a collaborative and inclusive workplace, prioritize continuous learning, and commit to environmental responsibility.

Contact: Hanna

Tel: +86 18029386958

Email: hanna@fshold.com

WhatsApp: +86 18029386958

Company Address: Lianfu Road 1 , Fuan Industrial Zone, Leliu Town, Shunde District, Foshan , Guangdong, China

Copyright © 2025 HOLD-www.holdmac.com |Sitemap Privacy Policy