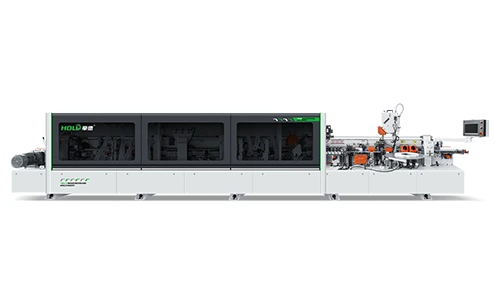

Automatic High-Speed Edge Banding Machine HD622J

Feature:

●Double gluing system: Gluing Unit 1:

Fast-Melting Adhesive + Upper Glue Pot Coating System + Automatic Glue Granule Supply; Gluing Unit 2: Lower EVA gluing system;

●Five-Wheel Pressing Unit:4 Steel Wheels + Steel Wheel Glue Scraper Device + 1 Silicone Wheel Mode. Each steel wheel is equipped with a glue scraper for quickly removing adhesive stuck to the pressing wheels; the silicone wheel ensures a stronger pressing effect.

●Two Sets of Edge Scrapers:Arc shaping for smooth edges; depending on the thickness of the edge banding, two sets of scrapers with different radii are used flexibly for trimming. This process integrates with trimming and polishing to achieve a perfect edge sealing effect.

●Flexible Flat Scraper: Removes excess adhesive and impurities from the board surface, ensuring the workpiece is clean and aesthetically pleasing.

●Cleaning Agent Device: Dilutes residual hot melt adhesive, making the board surface easier to clean.

Technical parameter

| Lifting | Electric lifting |

| Minimum sheet size | 60x120mm,50x300mm(Seal the long edge, with tracking available) |

| Feed speed |

14m-20m-23m/min |

| Tape thickness | 0.4-3mm |

| Sheet thickness | 10-60mm |

| Working air pressure | 0.6Mpa |

| Exterior dimensions |

8400x900x1700mm |

detail pictures

Product video