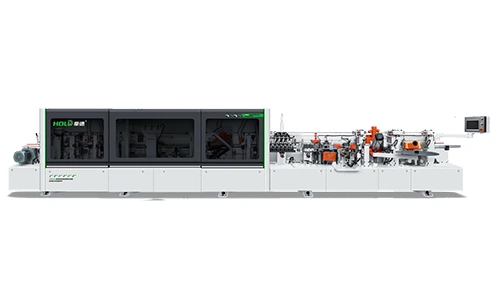

Automatic bevel/straight edge banding machine: HD783J

bevel/straight edge integrated banding machine

Feature:

● Bevel Pre-Milling + Straight Edge Pre-Milling:Through the milling process of the edge milling mechanism, the edge banding achieves the best state.

●panel heating unit: The panel heating unit heats the surface of the board before coating when the temperature is low, ensuring better adhesion of the adhesive and a more perfect edge sealing

● beveled edge adhesive coating + straight edge adhesive coating: The adhesive coating system for the panels ensures proper glue application with controlled quantity, good thermal conductivity, stable operation, uniform coating, stronger adhesion, and a more perfect edge sealing effect

● straight edge + angled edge pressing mechanism + hot air gun: The strong pressing force of the straight edge and angled edge pressing mechanism, combined with the hot air gun, ensures better adhesion and a tighter fit of the edge banding

● dual rail alignment: The dual rail alignment ensures quick and precise cutting of the front and rear edge banding, with the two saw blades aligned for high precision and efficiency

● Two sets of flat edge scraping + cleaning agent system: Flat edge scraping: Removes excess hot melt adhesive from the surface of the workpiece.

Cleaning agent system: Dilutes the residual hot melt adhesive, making it easier to clean

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Technical parameter

|

Lifting |

Electric lifting |

|

Feed Speed |

Beveled edge:14-16m/min Straight edge:14m/20m/23m/min |

|

Edge Banding Tape Thickness |

Bevel edge:0.6-1.0mm Straight edge:0.4-3mm |

|

Board Thickness |

Beveled edge:15-25mm(Vertical edge height 5mm,8mm)

Straight edge:10-60mm |

|

Bevel Angle |

45° (non-adjustable) |

|

Board Length |

≥200mm |

|

Board Width |

≥150mm |

|

Minimum Board Size |

200*150mm |

detail pictures

straight edge + angled edge pressing mechanism + h

beveled edge adhesive coating + straight edge adhe

Bevel Pre-Milling + Straight Edge Pre-Milling

Product video

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Our woodworking machinery factory values innovation, quality, and sustainability. We foster a collaborative and inclusive workplace, prioritize continuous learning, and commit to environmental responsibility.

Contact: Hanna

Tel: +86 18029386958

Email: hanna@fshold.com

WhatsApp: +86 18029386958

Company Address: Lianfu Road 1 , Fuan Industrial Zone, Leliu Town, Shunde District, Foshan , Guangdong, China

Copyright © 2025 HOLD-www.holdmac.com |Sitemap Privacy Policy