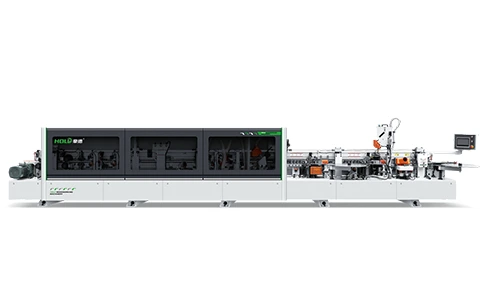

Automatic High-Speed Edge Banding Machine HD686J

Narrow Edge Banding Machine

Feature:

● Special pre-milling mechanism designed for narrow end heads of workpieces, capable of milling end heads with a width of ≥40mm.

●Narrow edge end head auxiliary feeding/side pressure device: specifically designed for narrow board edge banding, facilitating feeding, ensuring safety and stability, and improving efficiency.

●CNC lifting pressure beam reduces labor intensity, increases efficiency, and accuracy.

●Board heating unit.

●Gluing System 1: Upper gluing system + rapid adhesive melting device, with reserved PUR interface.

●Gluing System 2: Lower EVA gluing system.

●Six-wheel pressing: 5 steel wheels + steel wheel glue scraping device + 1 silicone wheel mode, providing more adherence during pressing, and quickly removing adhesive stuck on the pressing wheels.

●Conveyor reducer adopts high-efficiency hardened gear reducer, providing strong and powerful performance.

●Two sets of pneumatic edge avoidance scrapers.

●Equipped with flexible flat scraping, cleaning agent device,

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Technical parameter

|

Lifting |

Electric lifting |

|

Narrow board opening tracking speed |

16m/min |

|

Min processing size for short edges |

120mm*40mm(Narrow board tracking speed) |

|

Min processing size for long edges |

300*40mm(40mm end heads can be pre-milled) 300*40mm (The long edges of the workpiece can turn on corner rounding) |

|

Processing speed |

16m-20m-23m/min |

|

Feed speed |

14-20-23m/min |

|

Tape thickness |

0.4-3mm |

|

Sheet thickness |

10-60mm |

|

Working air pressure |

0.6Mpa |

|

Total Power |

26kw |

|

Exterior dimensions |

10000*960*1750mm |

detail pictures

Narrow Board End Head Auxiliary Feeding

Narrow Board Automatic Side Pressure Device

Lower EVA Gluing System

Pre-Milling Mechanism

Corner rounding

Two Sets of Edge Scraping

Product video

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Our woodworking machinery factory values innovation, quality, and sustainability. We foster a collaborative and inclusive workplace, prioritize continuous learning, and commit to environmental responsibility.

Contact: Hanna

Tel: +86 18029386958

Email: hanna@fshold.com

WhatsApp: +86 18029386958

Company Address: Lianfu Road 1 , Fuan Industrial Zone, Leliu Town, Shunde District, Foshan , Guangdong, China

Copyright © 2025 HOLD-www.holdmac.com |Sitemap Privacy Policy