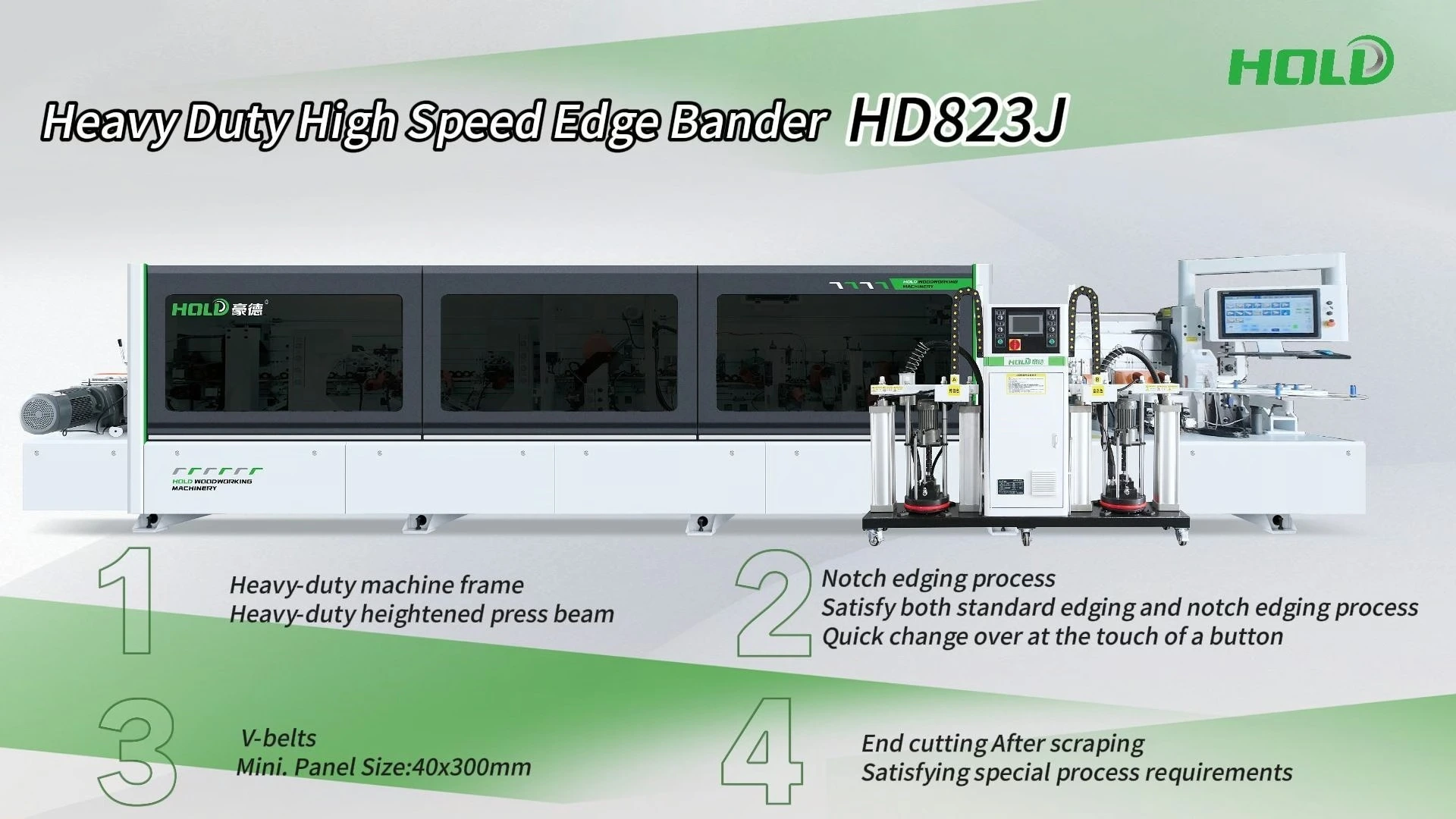

Heavy duty automatic high-speed edge banding machine: HD823J

- Heavy-duty machine frame with CNC machined to ensure the flatness of the table.

- Heavy-duty heightened press beam, compared with ordinary press beam, Heavy-duty heightened press beam greatly increases the rigidity and strength of the press beam to ensure the stability of the press beam during high rigidity operation.

- V-belts, Min.panel size: 300×40mm (Corner rounding On).

- Notch avoidance, can satisfy standard edge banding, also can cope with notch edge banding process, screen a key to quickly change over.

- End cutting behind the scraping, to satisfy the needs of special processes, greatly reducing the chances of special workpieces knocking boards off the corner.

- Industrial control system, fully intelligent control system, real-time data transmission, real-time understanding of the status of the equipment, production reports a key to get.

- CNC Lifting press beam, reduce labor intensity, increase efficiency and accuracy.

- Sorvo tape feeding, more accurate tape feeding.

- Swing pressing: eliminate tape dragging phenomenon. 5-post pressure rollers, 4 steel wheels + steel wheel glue clearing scraper device + 1 silicone wheel mode, pressing more obedient, quickly remove the glue stuck on the pressing wheel.

- Patented technology: HOLD patented Flat Scraping mechanism.

- Equipped with permanent magnet synchronous motor, higher efficiency, fast labelling response time, easy to match the high conveying speed, long term use, lower energy consumption.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Technical parameter

|

Lifting |

CNC lift |

|

Overall Dimensions |

About 8250x950x1800mm |

|

Feed Rate |

14-20-23m/min |

|

Edge Band Thickness |

0.4-1.2mm |

|

Board Thickness |

10-60mm |

|

Board Length |

≥120mm(Corner rounding On:≥300mm) |

|

Board Width |

≥40mm |

detail pictures

Notched edge banding process

Heavy-duty machine frame + Heavy-duty heightened press beams

Industrial control integrated operation

Fully Intelligent Control System

Narrow Board End Head Auxiliary Feeding

Separation Agent Device

Pre-Milling

Board Heating Unit

Gluing: Dual-Color PUR Non-Cleaning Glue Pot

Linear PUR Hot Melt Glue Pump Machine

Servo tape feeding + swing pressing

Rough trimming+Fine trimming

Horizontal Disc Scraping

HOLD patented: Flexible Flat Scraping

End cutting

5f402956fb5f76b95376bd0d7ce2cb6b (2)

Buffing

Permanent Magnet Synchronous Motor for Conveying

Product video

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Our woodworking machinery factory values innovation, quality, and sustainability. We foster a collaborative and inclusive workplace, prioritize continuous learning, and commit to environmental responsibility.

Contact: Hanna

Tel: +86 18029386958

Email: hanna@fshold.com

WhatsApp: +86 18029386958

Company Address: Lianfu Road 1 , Fuan Industrial Zone, Leliu Town, Shunde District, Foshan , Guangdong, China

Copyright © 2025 HOLD-www.holdmac.com |Sitemap Privacy Policy