Streamlining Your Process: The Benefits Of An Edge Banding Machine

Are you tired of wasting time and resources on manual edge banding processes? Look no further! In this article, we explore the numerous benefits of incorporating an edge banding machine into your workflow. From increased efficiency to improved product quality, streamlining your process with this innovative technology is sure to revolutionize your production line. Read on to discover how an edge banding machine can take your business to the next level.

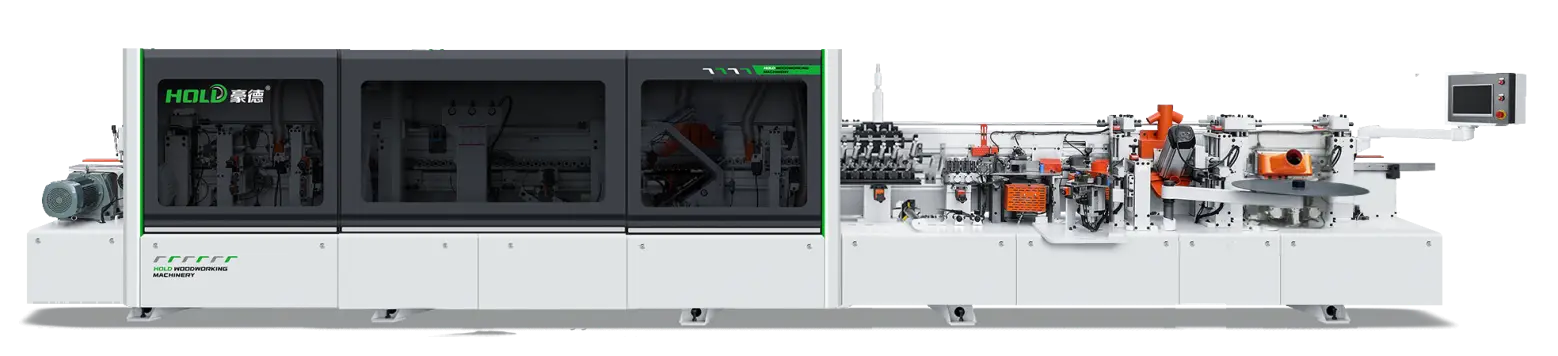

- Understanding the Importance of Edge Banding Machines

Edge banding machines are an essential tool in the woodworking industry, with a wide range of benefits and advantages for manufacturers and craftsmen alike. In this article, we will delve into the importance of edge banding machines and how they can streamline your process, ultimately improving the quality of your finished products.

Edge banding machines are specifically designed to apply edge banding material to the edges of wood panels, providing a clean and durable finish. This process not only enhances the aesthetic appeal of the final product but also improves its durability and longevity. By seamlessly covering the exposed edges of panels, edge banding machines help protect them from moisture, dust, and other elements that can cause damage over time.

One of the key benefits of using an edge banding machine is the efficiency and precision it offers. With automated features and advanced technology, these machines can apply edge banding material quickly and accurately, saving time and reducing the likelihood of errors. This not only increases productivity but also ensures a consistent and professional finish on every piece.

Moreover, edge banding machines come in a variety of sizes and configurations to accommodate different types of woodworking projects. Whether you are working on large-scale production or custom pieces, there is a machine that fits your specific needs. This flexibility allows manufacturers to streamline their processes and meet the demands of their customers more effectively.

In addition to improving efficiency and quality, edge banding machines also offer cost-saving benefits. By reducing labor costs and minimizing waste, these machines can help businesses improve their bottom line and increase profitability. With a faster production process and reduced material usage, manufacturers can produce more products in less time, ultimately increasing their output and revenue.

Furthermore, edge banding machines can also enhance the versatility and creativity of woodworking projects. With the ability to apply different types of edge banding materials, such as wood veneer, PVC, or melamine, craftsmen can customize their designs and create unique pieces that stand out in the market. This flexibility allows for more creative expression and innovation in woodworking projects.

In conclusion, edge banding machines play a vital role in the woodworking industry by improving efficiency, quality, and cost-effectiveness. With their ability to streamline processes, enhance durability, and increase productivity, these machines are a valuable investment for manufacturers and craftsmen looking to take their woodworking projects to the next level. By understanding the importance of edge banding machines and their many benefits, businesses can stay ahead of the competition and continue to deliver exceptional products to their customers.

- Maximizing Efficiency in Your Production Process

In today's fast-paced manufacturing industry, efficiency is key. Companies are constantly looking for ways to streamline their production processes in order to maximize output while minimizing costs. One way to achieve this is through the utilization of an edge banding machine. These machines are designed to automate the process of applying edge banding to various materials, such as wood, plastic, or metal, resulting in a more efficient and consistent end product.

Edge banding machines come in a variety of sizes and configurations, allowing companies to choose the model that best suits their specific needs. From small, tabletop models ideal for smaller projects, to large industrial machines capable of handling high-volume production, there is a machine available for every type of manufacturer.

One of the key benefits of using an edge banding machine is the time savings it provides. Traditional edge banding methods require manual labor and can be time-consuming, especially for larger projects. By automating the process with a machine, companies can significantly reduce the time it takes to complete a project, allowing for faster turnaround times and increased productivity.

In addition to time savings, edge banding machines also offer improved accuracy and consistency. By eliminating the potential for human error that comes with manual application, these machines are able to apply edge banding with precision and uniformity, resulting in a higher quality finished product. This consistency is especially important for companies that rely on repeatable results, such as furniture manufacturers or cabinet makers.

Furthermore, edge banding machines can help companies save on labor costs. By reducing the need for manual labor in the edge banding process, companies can reallocate their workforce to more productive tasks, ultimately improving overall efficiency and reducing costs. Additionally, the consistent and professional finish provided by an edge banding machine can help attract new customers and retain existing ones, leading to increased revenue and business growth.

Overall, investing in an edge banding machine can provide a wide range of benefits for companies looking to maximize efficiency in their production process. From time savings and improved accuracy to cost reductions and increased customer satisfaction, these machines offer a valuable tool for companies looking to stay competitive in today's market. By leveraging the capabilities of an edge banding machine, companies can streamline their production processes and achieve greater success in their industry.

- Achieving Professional and Polished Results

In today's fast-paced and competitive woodworking industry, it is crucial to streamline your process in order to achieve professional and polished results. One tool that can greatly aid in this endeavor is an edge banding machine. This cutting-edge machine is a must-have for any workshop looking to increase efficiency, improve quality, and save time and money.

An edge banding machine is a specialized piece of equipment designed to apply a thin strip of material, known as edge banding, to the exposed edges of a panel or piece of furniture. This process not only enhances the appearance of the finished product but also protects the edges from wear and tear, moisture, and other damaging elements. With an edge banding machine, you can achieve clean, seamless edges that give your projects a professional and polished look.

One of the key benefits of using an edge banding machine is its ability to streamline the production process. Without this machine, applying edge banding can be a time-consuming and labor-intensive task that requires attention to detail and precision. With an edge banding machine, however, you can automate this process, significantly reducing the time and effort required to complete each project. This means that you can increase your productivity, take on more projects, and meet tight deadlines with ease.

Another advantage of an edge banding machine is its ability to improve the quality of your work. By using a machine to apply edge banding, you can ensure consistent results every time. The machine applies the banding evenly and accurately, eliminating the risk of human error and ensuring that your edges are smooth and seamless. This level of precision and consistency is essential for achieving professional and polished results that will impress your clients and customers.

In addition to saving time and improving quality, an edge banding machine can also save you money in the long run. By automating the edge banding process, you can reduce waste and minimize the risk of costly mistakes. You can also minimize the need for rework, as the machine ensures that the banding is applied correctly the first time. This can result in significant cost savings over time, making an edge banding machine a wise investment for any woodworking business.

In conclusion, an edge banding machine is a valuable tool for any woodworking workshop looking to streamline their process and achieve professional and polished results. With its ability to save time, improve quality, and save money, this machine is a must-have for any business looking to stay ahead of the competition. If you want to take your woodworking projects to the next level, consider investing in an edge banding machine today.

- Saving Time and Labor Costs with Automation

In today's fast-paced manufacturing industry, time is money. Every minute wasted on inefficient processes can lead to lost profits and decreased productivity. This is where automation comes in, specifically with the use of edge banding machines. These machines are revolutionizing the way companies streamline their processes, ultimately saving time and labor costs.

Edge banding machines are used in the woodworking and furniture industries to apply a thin strip of material to the edges of furniture panels, giving them a finished look. Traditionally, this process was done manually, requiring skilled labor and taking up valuable time. However, with the introduction of edge banding machines, companies can now automate this process, resulting in significant time and labor savings.

One of the main benefits of using an edge banding machine is the speed at which it can apply edge banding material to panels. These machines are capable of processing multiple panels at once, significantly reducing the time it takes to complete a project. This increased efficiency allows companies to meet deadlines faster and take on more projects, ultimately increasing their overall profitability.

In addition to saving time, edge banding machines also reduce labor costs. With automation, companies no longer need as many skilled workers to manually apply edge banding material. This means they can reallocate their labor resources to other areas of the production process, further increasing efficiency and reducing costs.

Another advantage of edge banding machines is the consistency and quality of the finished product. Manual edge banding can often lead to errors and inconsistencies, resulting in a subpar final product. However, edge banding machines ensure that the edge banding material is applied evenly and accurately every time, resulting in a high-quality finish that meets customer expectations.

Furthermore, edge banding machines are versatile and can be used for a wide range of materials, including wood, PVC, and melamine. This versatility allows companies to work with a variety of materials and expand their product offerings, ultimately increasing their competitiveness in the market.

Overall, the benefits of using an edge banding machine are clear. By automating the edge banding process, companies can save time, reduce labor costs, increase efficiency, and improve the quality of their finished products. In today's competitive market, companies that invest in automation technology like edge banding machines are able to stay ahead of the competition and maximize their profits.

- Investing in Quality Equipment for Long-Term Success

Streamlining Your Process: The Benefits of an Edge Banding Machine - Investing in Quality Equipment for Long-Term Success

In the world of woodworking and cabinetry, efficiency is key. The ability to produce quality products quickly and consistently can make or break a business. One piece of equipment that can greatly streamline the production process is an edge banding machine. Investing in a high-quality edge banding machine can have a significant impact on the success of your business in the long run.

An edge banding machine is a piece of equipment used to apply thin strips of material, known as edge banding, to the edges of wooden panels. This process not only gives the panels a finished look but also helps to protect the edges from damage. Using an edge banding machine can greatly speed up the finishing process, as it eliminates the need for manual application of edge banding.

One of the main benefits of investing in an edge banding machine is the increase in efficiency it can provide. By automating the process of applying edge banding, you can significantly reduce the time it takes to finish a piece of furniture or cabinetry. This means you can complete more projects in less time, increasing your overall productivity and ultimately boosting your bottom line.

In addition to saving time, using an edge banding machine can also improve the quality of your finished products. Manual application of edge banding can be inconsistent, resulting in uneven edges and gaps between the edge banding and the panel. A quality edge banding machine will provide precise, uniform application of edge banding, ensuring a clean and professional finish every time.

Furthermore, investing in a high-quality edge banding machine can also save you money in the long run. While the initial cost of purchasing the machine may seem high, the efficiency and consistency it provides can ultimately lead to cost savings. By reducing the amount of time and labor required to finish a project, you can lower your overall production costs and increase your profit margins.

When choosing an edge banding machine, it is important to consider the quality of the equipment. Opting for a cheaper, lower-quality machine may save you money in the short term, but it could end up costing you more in the long run due to frequent breakdowns and repairs. Investing in a reputable brand with a track record of reliability and durability is essential to ensure that your edge banding machine will continue to perform well for years to come.

In conclusion, investing in a quality edge banding machine is a smart decision for any woodworking or cabinetry business looking to streamline their process and increase efficiency. By automating the process of applying edge banding, you can save time, improve the quality of your finished products, and ultimately save money in the long run. With the right equipment, you can set your business up for long-term success and continued growth.

Conclusion

In conclusion, the benefits of incorporating an edge banding machine into your production process are clear and numerous. From increased efficiency and productivity to improved quality and consistency in your finished products, the use of this technology can truly streamline your operations and help you stay ahead of the competition. Investing in an edge banding machine is a smart decision for any woodworking or manufacturing business looking to enhance their processes and deliver top-notch results to their customers. So why wait? Take the plunge and start reaping the rewards of this invaluable tool today.