The Ultimate Guide To Industrial Woodworking Machines

Are you looking to elevate your woodworking skills and increase efficiency in your workshop? Look no further than "The Ultimate Guide to Industrial Woodworking Machines." In this comprehensive article, we break down everything you need to know about these powerful tools, from basic functions to advanced techniques. Whether you're a seasoned craftsman or just getting started, this guide has something for everyone. Let's explore the endless possibilities of industrial woodworking machines together.

- Understanding the Different Types of Industrial Woodworking Machines

Industrial woodworking machines are essential tools in the manufacturing and production of various wood products. These machines play a crucial role in shaping, cutting, and finishing wood materials for different applications. Understanding the different types of industrial woodworking machines is crucial for anyone in the woodworking industry.

The first type of industrial woodworking machine is the table saw. Table saws are versatile machines that are used for making straight cuts in wood. They consist of a circular blade mounted on an arbor and a flat table surface for supporting the workpiece. Table saws come in various sizes and configurations, including portable and stationary models. They are commonly used for ripping, cross-cutting, and mitering wood.

Another important type of industrial woodworking machine is the planer. Planers are used for flattening and smoothening the surface of rough lumber. They consist of a cutting head with multiple blades that shave off thin slices of wood to achieve a desired thickness. Planers are commonly used in furniture making and cabinetry to prepare wood materials for further processing.

Jointers are another type of industrial woodworking machine that is essential for creating straight and flat edges on wood pieces. Jointers consist of a long, flat bed and a rotating cutter head that removes material from the edge of the workpiece. Jointers are commonly used in conjunction with planers to prepare wood for joining and assembly.

The band saw is a versatile industrial woodworking machine that is used for making curved and irregular cuts in wood. Band saws consist of a continuous loop of teethed blade stretched between two wheels. The blade moves in a vertical or horizontal motion, allowing for precise and intricate cuts. Band saws are commonly used in cutting curves, resawing, and cutting irregular shapes in wood materials.

Another important type of industrial woodworking machine is the router. Routers are versatile machines that are used for cutting intricate designs, profiles, and joinery in wood materials. They consist of a spinning cutter mounted on a motor that can be adjusted for depth and height. Routers are commonly used in furniture making, cabinetry, and woodworking crafts for creating decorative edges and patterns.

In conclusion, industrial woodworking machines play a crucial role in the woodworking industry by shaping, cutting, and finishing wood materials. Understanding the different types of industrial woodworking machines is essential for anyone working in the woodworking industry. By knowing the capabilities and functions of each type of machine, woodworkers can choose the right tool for their specific woodworking needs and achieve precise and professional results.

- Choosing the Right Industrial Woodworking Machine for Your Needs

Industrial woodworking machines are essential tools for any woodworking business or workshop. These machines are designed to streamline and enhance the woodworking process, increasing productivity and efficiency. However, with a wide range of options available on the market, choosing the right industrial woodworking machine for your specific needs can be a daunting task. In this ultimate guide, we will discuss the factors to consider when selecting an industrial woodworking machine and provide recommendations for different types of machines based on your requirements.

When choosing an industrial woodworking machine, it is important to first consider the type of woodworking projects you will be working on. Different machines are designed for specific tasks, such as cutting, shaping, or finishing the wood. For example, a table saw is a versatile machine that is ideal for cutting large pieces of wood, while a jointer is best suited for creating smooth, flat surfaces on wooden boards. By understanding the requirements of your projects, you can narrow down the options and choose a machine that meets your needs.

Another important factor to consider is the size and capacity of the machine. Industrial woodworking machines come in a variety of sizes, from small benchtop models to large, floor-standing units. The size of the machine should be proportional to the size of your workspace and the scale of your projects. Additionally, consider the capacity of the machine in terms of the maximum thickness and width of the wood it can handle. Choosing a machine with the right size and capacity ensures that you can work efficiently and effectively on your projects.

In addition to size and capacity, it is important to consider the features and specifications of the machine. Look for machines with adjustable settings, such as blade depth and speed control, to customize the machine to suit your specific needs. Other features to consider include dust collection systems, safety guards, and ergonomic design for comfortable use. By choosing a machine with the right features, you can improve the quality of your work and ensure a safe working environment.

When selecting an industrial woodworking machine, it is also important to consider the brand and reputation of the manufacturer. Look for well-known and reputable brands that have a track record of producing high-quality machines. By choosing a machine from a trusted manufacturer, you can be confident in the durability and reliability of the machine, ensuring that it will perform well for years to come.

In conclusion, choosing the right industrial woodworking machine for your needs requires careful consideration of factors such as the type of projects you will be working on, the size and capacity of the machine, its features and specifications, and the reputation of the manufacturer. By taking the time to research and evaluate your options, you can select a machine that will help you achieve your woodworking goals and enhance your productivity. So, do your research and invest in the right industrial woodworking machine for your workshop.

- Setting Up and Operating Industrial Woodworking Machines Safely

Industrial woodworking machines are powerful tools that can help businesses boost their productivity and efficiency when handling wood projects. However, without proper knowledge and safety precautions, operating these machines can be extremely dangerous. In this comprehensive guide, we will delve into the ins and outs of setting up and operating industrial woodworking machines safely.

Setting up industrial woodworking machines is the first step towards a successful woodworking project. Before starting any work, it is essential to ensure that the machine is placed on a level surface and is securely anchored to prevent any accidents. Additionally, it is crucial to read the manufacturer's instructions carefully and follow all safety guidelines provided. This includes wearing appropriate personal protective equipment such as safety goggles, ear protection, and gloves.

Once the machine is properly set up, it is important to familiarize oneself with its various components and functions. Industrial woodworking machines come in different types, such as table saws, band saws, jointers, planers, and sanders, each serving a specific purpose. Understanding how to properly operate these machines is key to achieving precise and accurate results in woodworking projects.

When operating industrial woodworking machines, safety should always be the top priority. Always keep your hands and fingers away from moving parts, and never remove any safety guards or devices. Before starting the machine, make sure that all workpieces are properly secured and that the cutting blades are in good condition. It is also crucial to maintain a safe distance from the machine while it is in operation to prevent any accidents.

In addition to safety precautions, it is essential to maintain industrial woodworking machines regularly to ensure optimal performance. This includes keeping the machines clean and well-lubricated, checking for any loose or damaged parts, and replacing worn-out components as needed. Regular maintenance not only prolongs the lifespan of the machines but also reduces the risk of accidents due to malfunctioning equipment.

In conclusion, industrial woodworking machines are valuable tools that can greatly increase productivity and efficiency in woodworking projects. However, it is imperative to set up and operate these machines safely to prevent any accidents or injuries. By following the tips and guidelines outlined in this guide, woodworkers can enjoy the benefits of industrial woodworking machines while ensuring their safety in the workplace.

- Maintaining and Repairing Industrial Woodworking Machines for Longevity

Industrial woodworking machines are essential tools for any woodworking operation, from small workshops to large factories. These machines are designed to handle heavy-duty tasks and produce high-quality wood products efficiently. However, like any machinery, industrial woodworking machines require regular maintenance and repair to ensure their longevity and optimal performance.

Maintaining industrial woodworking machines is crucial to prolonging their lifespan and preventing costly breakdowns. Regularly cleaning and lubricating the machines can help prevent dust and debris build-up, which can cause components to wear out prematurely. It is also important to inspect the machines for any signs of wear and tear, such as loose bolts or belts, and replace them as needed.

In addition to regular maintenance, it is essential to follow the manufacturer's guidelines for operating the machines safely. Improper usage can not only damage the machines but also pose a safety risk to the operators. Proper training on how to use the machines correctly can help prevent accidents and ensure efficient operation.

When it comes to repairing industrial woodworking machines, it is crucial to address the issue promptly to prevent further damage. It is recommended to have a qualified technician inspect and repair the machines to ensure they are fixed correctly and safely. It is also advisable to keep spare parts on hand for quick replacements when needed.

Overall, the key to maintaining and repairing industrial woodworking machines for longevity is to prioritize regular maintenance, adhere to safety guidelines, and address any issues promptly. By following these best practices, woodworkers can ensure that their machines are operating at their best and producing high-quality products consistently.

Industrial woodworking machines play a vital role in the woodworking industry, and taking care of them is essential for ensuring their longevity and optimal performance. By following the tips outlined in this article, woodworkers can keep their machines in top condition and avoid costly repairs and downtime. Remember, investing time and effort in maintaining and repairing industrial woodworking machines is an investment in the success of your woodworking operation.

- Maximizing Efficiency and Output with Industrial Woodworking Machines

Industrial woodworking machines play a crucial role in maximizing efficiency and output in woodworking operations. These machines are specifically designed to handle large-scale production, ensuring that woodworkers can meet the demands of their customers while maintaining high-quality standards. In this ultimate guide, we will explore the various types of industrial woodworking machines available on the market today and discuss how they can help businesses achieve their production goals.

One of the key benefits of industrial woodworking machines is their ability to streamline the production process. These machines are equipped with advanced technology and automation features that allow woodworkers to complete tasks quickly and efficiently. From cutting and shaping to sanding and finishing, industrial woodworking machines can perform a wide range of functions with precision and consistency. This not only helps to reduce labor costs but also minimizes the risk of errors and defects in the finished products.

Another advantage of industrial woodworking machines is their ability to handle heavy workloads with ease. Whether you are working on large furniture pieces or intricate cabinetry, these machines are designed to withstand the demands of high-volume production. With features such as powerful motors, sturdy frames, and adjustable settings, industrial woodworking machines can handle a variety of tasks without compromising on quality or performance.

In addition to maximizing efficiency, industrial woodworking machines also help businesses increase their output. By automating repetitive tasks and minimizing production times, these machines allow woodworkers to produce more finished products in a shorter amount of time. This is especially important for businesses that are looking to scale up their operations and meet growing market demands. With the right industrial woodworking machines in place, companies can increase their production capacity and expand their customer base.

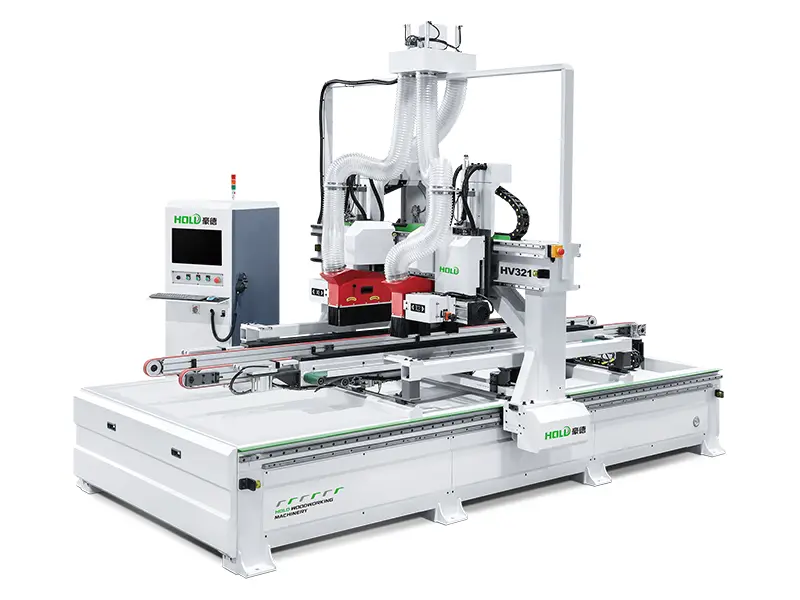

When it comes to choosing the right industrial woodworking machines for your business, it is important to consider your specific needs and requirements. There are many different types of machines available, each designed for specific tasks and applications. From table saws and planers to CNC routers and edge banders, the options are virtually endless. It is essential to do thorough research and select machines that are well-suited to your production goals and budget.

In conclusion, industrial woodworking machines are essential tools for businesses looking to maximize efficiency and output in their woodworking operations. These machines offer a wide range of benefits, from streamlining production processes to increasing output and quality. By investing in the right machines and technology, woodworkers can take their production capabilities to the next level and stay competitive in the industry. Whether you are a small woodworking shop or a large manufacturing facility, industrial woodworking machines can help you achieve your production goals and drive success in your business.

Conclusion

In conclusion, industrial woodworking machines are essential tools for any woodworking business or enthusiast looking to efficiently and effectively produce high-quality wood products. This ultimate guide has provided an in-depth look at the various types of industrial woodworking machines available, their functions, and how to choose the right one for your specific needs. By investing in the right machinery and understanding how to use them properly, you can increase productivity, improve the quality of your products, and take your woodworking skills to the next level. Whether you are a beginner or a seasoned professional, having a solid understanding of industrial woodworking machines is key to achieving success in the woodworking industry. So, take the time to research, explore different options, and invest in the right equipment to help you reach your woodworking goals.