The Ultimate Guide To Industrial Woodworking Machines: How To Choose The Right Tools For Your Workshop1

Are you looking to take your woodworking skills to the next level? Do you want to equip your workshop with the best tools for the job? Look no further than our comprehensive guide to industrial woodworking machines. In this article, we break down everything you need to know about selecting the right tools for your workshop, ensuring you have the best equipment to create top-quality projects. Keep reading to learn how to choose the perfect woodworking machines for your needs.

- Understanding the Different Types of Industrial Woodworking Machines

Industrial woodworking machines are essential tools for any workshop or production facility that deals with wood materials. These machines come in a variety of types, each designed for specific tasks and applications. In this comprehensive guide, we will explore the different types of industrial woodworking machines and how to choose the right tools for your workshop.

1. Table saws: Table saws are perhaps the most common type of industrial woodworking machine. These versatile tools are used for straight cuts, ripping, and crosscutting wood materials. There are several types of table saws, including cabinet saws, contractor saws, and portable saws. When choosing a table saw for your workshop, consider factors such as power, blade size, and safety features.

2. Band saws: Band saws are another essential tool in industrial woodworking. These machines use a continuous loop of blade stretched between two wheels to make curved cuts, resawing, and cutting irregular shapes. Band saws come in various sizes and configurations, including vertical and horizontal models. When selecting a band saw, consider factors such as throat capacity, blade speed, and cutting capacity.

3. Planers: Planers are used to smooth and flatten wood surfaces, making them essential for woodworking projects that require precise dimensions. These machines come in various sizes and types, including benchtop planers, thickness planers, and hand planers. When choosing a planer, consider factors such as cutting width, cutting depth, and feed rate.

4. Jointers: Jointers are used to create straight edges and flat surfaces on rough lumber, making them essential for woodworking projects that require precise joinery. These machines come in various sizes and types, including benchtop jointers, hand jointers, and combo jointer-planer machines. When selecting a jointer, consider factors such as cutting width, cutting depth, and fence adjustability.

5. Router tables: Router tables are used for shaping, cutting, and profiling wood materials, making them essential for woodworking projects that require intricate details. These machines come in various sizes and configurations, including benchtop router tables and stand-alone router tables. When choosing a router table, consider factors such as horsepower, table size, and fence adjustability.

In conclusion, industrial woodworking machines are essential tools for any workshop or production facility that deals with wood materials. By understanding the different types of industrial woodworking machines and how to choose the right tools for your workshop, you can enhance productivity, efficiency, and safety in your woodworking projects. Choose the machines that best suit your specific needs and requirements to achieve the best results in your woodworking endeavors.

- Factors to Consider When Selecting Woodworking Tools for Your Workshop

When setting up a woodworking workshop, one of the most important factors to consider is the selection of the right industrial woodworking machines. Having the appropriate tools not only ensures the quality of your work but also improves efficiency and productivity. In this ultimate guide, we will discuss the key factors to consider when selecting woodworking tools for your workshop.

1. Type of Woodworking Projects:

The first consideration when choosing industrial woodworking machines is the type of projects you will be working on. Different tools are used for different tasks, so it is important to determine whether you will be working on large-scale projects, intricate designs, or simple DIY projects. This will help you narrow down your options and choose the tools that are most suitable for your needs.

2. Size of Workshop:

Another important factor to consider is the size of your workshop. Industrial woodworking machines can take up a significant amount of space, so it is essential to determine if you have enough room to accommodate the tools you need. Additionally, consider the layout of your workshop and how the machines will fit into the space. This will help you optimize workflow and make the most of your workspace.

3. Budget:

Your budget is also a crucial factor when selecting woodworking tools for your workshop. Industrial machines can be expensive, so it is essential to set a budget and stick to it. Consider the cost of the machines, as well as any additional accessories or maintenance required. It is important to strike a balance between quality and affordability to ensure that you get the best value for your money.

4. Quality and Durability:

When choosing industrial woodworking machines, it is important to prioritize quality and durability. Look for machines that are made from high-quality materials and are built to last. This will ensure that your tools can withstand heavy use and provide consistent performance over time. Investing in quality machines may require a higher upfront cost, but it will pay off in the long run by reducing the need for repairs or replacements.

5. Power and Performance:

The power and performance of industrial woodworking machines are crucial considerations when selecting tools for your workshop. Make sure to choose machines that have sufficient power to handle the tasks you need to complete. Consider the speed, accuracy, and efficiency of the machines to ensure that they meet your requirements. Additionally, look for machines with features that improve performance, such as adjustable speed settings, dust collection systems, and safety features.

In conclusion, choosing the right industrial woodworking machines for your workshop is a critical decision that can impact the quality and efficiency of your work. By considering factors such as the type of projects, size of workshop, budget, quality and durability, and power and performance, you can make informed decisions that will help you select the best tools for your needs. With the right tools in your workshop, you can take your woodworking projects to the next level and achieve professional results.

- Comparing the Cost and Quality of Industrial Woodworking Machines

Industrial woodworking machines are essential tools for any woodworking workshop, as they help streamline production, increase efficiency, and improve the overall quality of finished products. However, with so many options available on the market, choosing the right machines can be a daunting task. In this article, we will explore the key factors to consider when comparing the cost and quality of industrial woodworking machines, helping you make informed decisions for your workshop.

When it comes to industrial woodworking machines, there are two main considerations to keep in mind: cost and quality. The cost of a machine is often the first factor that comes to mind, as it directly impacts your budget and overall investment in your workshop. However, it is important not to skimp on quality to save a few bucks, as a high-quality machine will not only last longer but also deliver better results.

When comparing the cost of industrial woodworking machines, it is important to consider both the initial investment and the long-term costs. While a cheaper machine may seem like a more budget-friendly option upfront, it may end up costing you more in the long run due to maintenance, repairs, and replacement parts. On the other hand, a higher-priced machine may have a higher upfront cost but lower long-term costs, as it is built to last and requires less maintenance.

In addition to cost, quality is another important factor to consider when choosing industrial woodworking machines. The quality of a machine can greatly impact its performance, durability, and overall efficiency. A high-quality machine will be constructed with durable materials, feature precision engineering, and come with advanced features that enhance its functionality.

To assess the quality of industrial woodworking machines, look for machines from reputable manufacturers with a history of producing reliable and high-performance tools. Consider the materials used in construction, such as cast iron or steel, as well as the precision of the machine's components. Pay attention to features such as motor power, cutting capacity, and safety mechanisms, as these can greatly impact the machine's performance and longevity.

When comparing the cost and quality of industrial woodworking machines, it is important to strike a balance between the two. While cost is an important factor, it should not be the sole determining factor in your decision-making process. Instead, prioritize quality and performance, even if it means investing a bit more upfront. Remember, a high-quality machine will not only deliver better results but also save you money in the long run by reducing maintenance and repair costs.

In conclusion, when choosing industrial woodworking machines for your workshop, consider both the cost and quality of the machines. Invest in high-quality machines from reputable manufacturers, even if they come with a higher price tag, as they will deliver superior performance and durability in the long run. By carefully comparing the cost and quality of industrial woodworking machines, you can make informed decisions that will benefit your workshop for years to come.

- Tips for Maintaining and Extending the Lifespan of Your Workshop Tools

Industrial woodworking machines are essential tools for any workshop that specializes in woodworking. These powerful machines can help increase productivity, precision, and efficiency in the woodworking process. However, like any other tool, it is important to properly maintain and care for these machines in order to extend their lifespan and ensure optimal performance.

One of the most important tips for maintaining industrial woodworking machines is to regularly clean and lubricate them. Dust, debris, and wood shavings can quickly build up on the machines, causing them to clog and malfunction. By regularly cleaning the machines with a soft brush or compressed air, you can prevent this buildup and ensure that the machines operate smoothly. Additionally, it is important to regularly lubricate the moving parts of the machines to prevent wear and tear.

Another important tip for extending the lifespan of industrial woodworking machines is to check and replace any worn or damaged parts. Over time, parts such as blades, belts, and bearings can become worn out and need to be replaced. By regularly inspecting the machines and replacing any damaged parts, you can prevent further damage and ensure that the machines continue to operate effectively.

It is also important to use the machines properly and according to the manufacturer's instructions. Using the machines for tasks that they are not designed for, or operating them at improper speeds or settings, can cause unnecessary strain and wear on the machines. By following the manufacturer's instructions and recommendations, you can ensure that the machines operate efficiently and safely.

Regular maintenance and inspection of industrial woodworking machines can help prevent costly repairs and downtime. By implementing a regular maintenance schedule and following these tips, you can extend the lifespan of your machines and keep them operating at peak performance. With proper care and maintenance, your industrial woodworking machines can continue to help you produce high-quality woodworking projects for years to come.

- Upgrading Your Workshop: Investing in Advanced Woodworking Machinery Features

Industrial woodworking machines are essential tools for any woodworking workshop looking to enhance efficiency, precision, and productivity. In this ultimate guide, we will delve into the various aspects of choosing the right tools for upgrading your workshop, with a particular focus on investing in advanced woodworking machinery features.

When it comes to upgrading your workshop, investing in advanced woodworking machinery features is crucial to take your woodworking projects to the next level. These features can significantly improve the quality of your work and streamline your production processes. From increased precision and accuracy to enhanced safety and productivity, advanced machinery features offer a wide range of benefits for woodworkers of all skill levels.

One of the key aspects to consider when choosing industrial woodworking machines is the type of machinery features that will best suit your specific needs. For example, if you primarily work with large pieces of wood, you may want to invest in a machine with a high-capacity cutting capacity. On the other hand, if you specialize in intricate details and fine woodworking, a machine with advanced precision controls and fine-tuning capabilities may be more suitable.

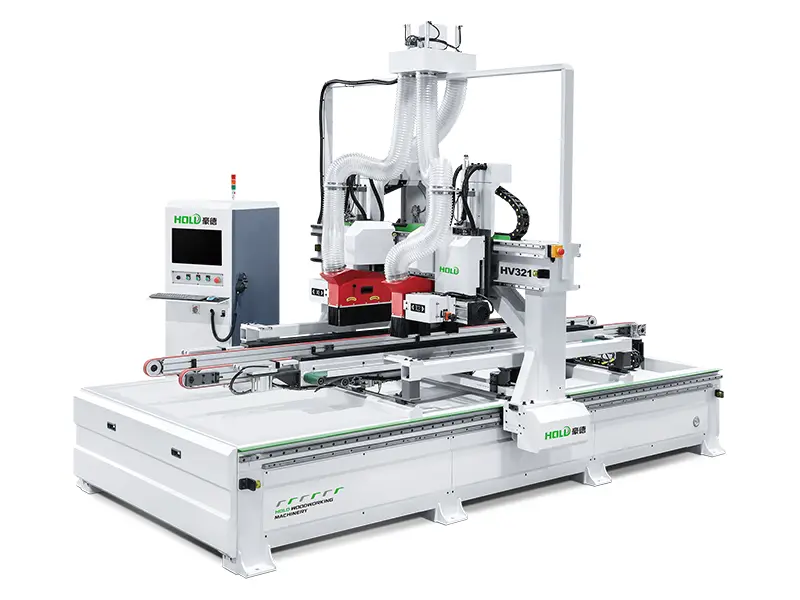

Another important factor to consider when upgrading your workshop is the level of automation and programmability offered by the woodworking machinery. Advanced features such as computer numerical control (CNC) technology can revolutionize the way you approach your woodworking projects by allowing for precise, repeatable cuts and intricate designs that would be nearly impossible to achieve manually.

In addition to precision and automation, safety is a crucial consideration when investing in advanced woodworking machinery features. Look for machines with built-in safety features such as emergency stop buttons, automatic blade guards, and safety sensors to protect yourself and your employees from potential accidents and injuries.

Furthermore, consider the overall durability and reliability of the machinery features you are considering. Industrial woodworking machines are a significant investment, and you want to ensure that the tools you choose will stand the test of time and provide consistent performance for years to come.

Finally, budget considerations are important when upgrading your workshop with advanced woodworking machinery features. While these machines can be a significant investment upfront, the long-term benefits in terms of improved efficiency, quality, and productivity make them well worth the cost.

In conclusion, investing in advanced woodworking machinery features is a smart decision for woodworkers looking to upgrade their workshop and take their projects to the next level. By considering factors such as precision, automation, safety, durability, and budget, you can choose the right tools that will enhance your woodworking capabilities and help you achieve your creative vision. Industrial woodworking machines are essential tools for any serious woodworker, and choosing the right features will make a world of difference in the quality and efficiency of your work.

Conclusion

In conclusion, selecting the right industrial woodworking machines for your workshop is key to ensuring efficiency and quality in your woodworking projects. By considering factors such as your budget, space limitations, and the type of woodworking tasks you frequently undertake, you can make an informed decision on which tools are best suited for your needs. With the right machines in place, you can take your woodworking skills to the next level and create professional-grade products with ease. So, invest in the right tools and watch your workshop thrive. Happy woodworking!