The Latest Advancements In CNC Router Technology

Are you curious about the latest advancements in CNC router technology? Look no further! In this article, we will explore the cutting-edge innovations that are revolutionizing the manufacturing industry. From increased precision to enhanced efficiency, these advancements are shaping the future of CNC routing. Join us as we delve into the exciting world of CNC router technology and discover how these advancements are changing the game.

- Introduction to CNC Router Technology

CNC (Computer Numerical Control) router technology has revolutionized the manufacturing industry in recent years, offering unparalleled precision and efficiency in cutting and shaping materials. From woodworking to metal fabrication, CNC router machines have become essential tools for businesses looking to streamline their production processes and produce high-quality results.

One of the key advancements in CNC router technology is the integration of advanced cutting tools and software. Modern CNC router machines are equipped with a wide variety of cutting tools, ranging from standard end mills to specialized bits for specific applications. These tools are controlled by sophisticated software programs that allow operators to design and execute complex cutting patterns with ease. The use of advanced cutting tools and software has greatly expanded the capabilities of CNC router machines, allowing manufacturers to achieve intricate designs and precise cuts that were previously impossible.

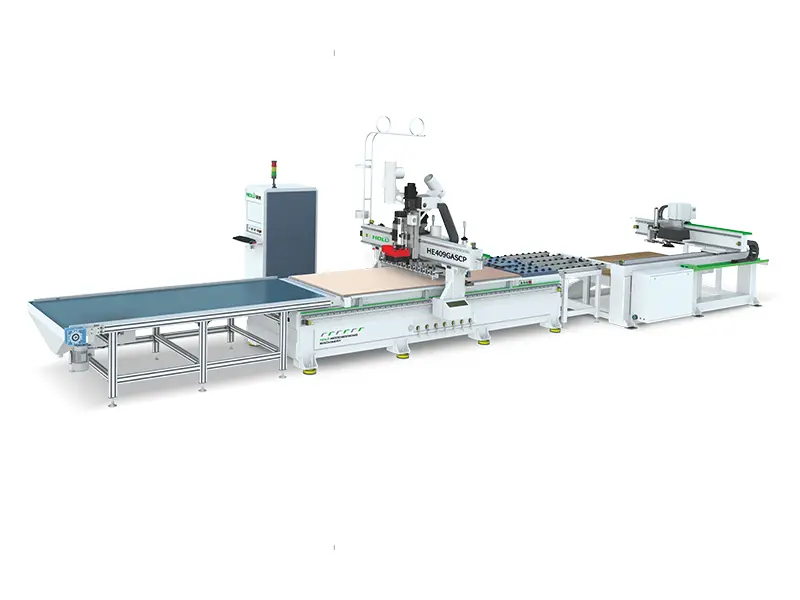

Another major development in CNC router technology is the incorporation of robotic automation. Many modern CNC router machines are equipped with robotic arms that can automatically load and unload materials, change cutting tools, and perform other tasks without human intervention. This automation not only increases the efficiency of the manufacturing process but also improves safety by reducing the risk of accidents caused by human error. The integration of robotic automation has made CNC router machines more versatile and adaptable to a wide range of production environments.

In addition to advanced cutting tools and robotic automation, CNC router technology has also seen significant improvements in machine design and construction. Modern CNC router machines are built with high-quality components and precision engineering to ensure smooth operation and long-lasting performance. Many machines feature rigid frames, high-speed spindles, and advanced motion control systems that enable them to achieve fast cutting speeds and high levels of accuracy. These enhancements have made CNC router machines more reliable and robust, allowing manufacturers to meet the demands of modern production environments.

Overall, the latest advancements in CNC router technology have transformed the manufacturing industry by providing businesses with the tools they need to produce high-quality products efficiently and cost-effectively. With advanced cutting tools, robotic automation, and precision engineering, CNC router machines offer unparalleled capabilities for cutting and shaping a wide range of materials. As the technology continues to evolve, we can expect to see even greater advancements in CNC router technology that will further revolutionize the manufacturing industry and drive innovation in product design and production processes.

- Key Features of the Latest CNC Router Models

As technology continues to advance, CNC router machines have also seen significant improvements in recent years. These machines have become essential tools in the manufacturing industry, offering precise and efficient cutting, carving, and engraving capabilities. In this article, we will delve into the key features of the latest CNC router models that make them stand out in the market.

One of the most notable advancements in CNC router technology is the integration of advanced software systems. These software systems allow for more complex designs to be created with ease, providing users with greater flexibility and creativity in their projects. Additionally, these software systems often come with built-in design libraries and tools that streamline the design process and enhance overall efficiency.

Another key feature of the latest CNC router models is improved precision and accuracy. Thanks to advancements in machine calibration and control systems, modern CNC routers are capable of producing incredibly detailed and intricate designs with minimal margin for error. This level of precision is essential for industries that require high-quality, consistent results, such as aerospace and automotive manufacturing.

In addition to precision, modern CNC router machines are also equipped with faster cutting speeds and higher production capacities. This means that manufacturers can produce more parts in less time, resulting in increased productivity and cost savings. The ability to meet tight deadlines and large production volumes is a significant advantage for businesses looking to stay competitive in today's fast-paced market.

Furthermore, the latest CNC router models often feature improved safety features and user-friendly interfaces. Safety sensors and emergency stop buttons are standard on most machines, ensuring a secure working environment for operators. Additionally, touchscreen control panels and intuitive software interfaces make it easy for users to program and operate the machine, reducing the learning curve for new users.

One of the most exciting developments in CNC router technology is the integration of automation and robotics. Some of the latest models come equipped with robotic arms and automated material handling systems, further streamlining the manufacturing process and reducing labor costs. These advanced features enable manufacturers to operate more efficiently and consistently, even in high-volume production environments.

In conclusion, the latest advancements in CNC router technology have revolutionized the manufacturing industry, providing businesses with the tools they need to stay competitive in today's market. From advanced software systems to improved precision and automation capabilities, these machines offer a range of benefits that can significantly enhance productivity and efficiency. As technology continues to evolve, it is clear that CNC router machines will continue to play a vital role in the future of manufacturing.

- Advantages of Upgrading to the Newest CNC Router Technology

In today's rapidly evolving manufacturing industry, staying up-to-date with the latest advancements in technology is crucial for staying competitive. One area where this is especially important is in CNC router machines, which play a significant role in the production process for many companies.

Advantages of Upgrading to the Newest CNC Router Technology

One of the key advantages of upgrading to the newest CNC router technology is increased efficiency. Newer machines are equipped with more advanced features that can significantly speed up the production process. For example, some of the latest CNC routers are capable of faster cutting speeds and higher acceleration rates, allowing for quicker turnaround times on projects. This not only improves productivity but also reduces lead times, which can be a significant competitive advantage in today's fast-paced market.

In addition to increased efficiency, upgrading to the newest CNC router technology can also result in higher precision and accuracy. Newer machines are equipped with more advanced control systems and sensors that can provide real-time feedback on the cutting process. This allows for more precise cuts, resulting in higher quality finished products. Improved accuracy can also help reduce waste and improve overall production quality, leading to cost savings in the long run.

Another advantage of upgrading to the newest CNC router technology is the ability to take on more complex projects. Advanced features such as multi-axis cutting and automatic tool changers allow for a wider range of capabilities, enabling companies to tackle more intricate designs and achieve higher levels of customization. This can open up new opportunities for business growth and expansion, as companies are able to take on a wider variety of projects for a more diverse customer base.

Furthermore, newer CNC router technology often includes enhanced safety features that can help protect workers and prevent accidents in the workplace. For example, some machines are equipped with sensors that can detect any abnormalities in the cutting process and automatically shut down the machine if necessary. This helps create a safer working environment for employees and reduces the risk of injuries on the job.

Overall, upgrading to the newest CNC router technology can bring a wide range of benefits to companies in the manufacturing industry. From increased efficiency and precision to the ability to take on more complex projects and improved safety features, investing in the latest advancements in CNC router technology can help companies stay competitive and grow their business in today's fast-paced market.

- Innovations in CNC Router Software and Automation

Innovations in CNC Router Software and Automation

CNC router technology has seen significant advancements in recent years, particularly in the realm of software and automation. These innovations have revolutionized the way CNC machines operate, making them more efficient, accurate, and user-friendly than ever before. From enhanced programming capabilities to advanced automation features, the latest advancements in CNC router technology are truly transforming the manufacturing industry.

One of the key innovations in CNC router software is the development of more powerful and intuitive programming tools. With the latest software updates, users can now create complex designs and intricate patterns with ease, thanks to advanced algorithms and user-friendly interfaces. These improvements have significantly reduced the learning curve for new users, allowing them to harness the full potential of their CNC router machines in record time.

In addition to improved programming capabilities, CNC router software now also boasts enhanced automation features. These features allow users to streamline their workflow, increase productivity, and minimize errors. For example, automatic tool changers can now be programmed to switch out tools on the fly, reducing downtime and maximizing efficiency. Similarly, advanced nesting algorithms can optimize material usage and reduce waste, saving both time and money in the production process.

Another key innovation in CNC router technology is the integration of IoT (Internet of Things) capabilities. By connecting CNC machines to the internet, manufacturers can now monitor and control their equipment remotely, from anywhere in the world. This level of connectivity has revolutionized the way CNC machines are operated, allowing for greater flexibility and efficiency in production processes.

Moreover, the latest advancements in CNC router technology have also paved the way for greater customization and personalization. With the ability to create intricate designs and patterns, CNC routers can now produce highly detailed and unique products, catering to a wider range of customer needs. This level of customization has opened up new opportunities for manufacturers, allowing them to differentiate themselves in a competitive market.

Overall, the latest advancements in CNC router technology have transformed the way manufacturers operate, making production processes more efficient, accurate, and versatile. With enhanced software capabilities, advanced automation features, and IoT connectivity, CNC router machines are now more powerful than ever before. As technology continues to evolve, we can expect even more groundbreaking innovations in the world of CNC routing, revolutionizing the manufacturing industry as we know it.

- Future Trends in CNC Router Technology Development

CNC (Computer Numerical Control) router technology has been rapidly advancing in recent years, with new innovations constantly being introduced to improve efficiency, accuracy, and versatility. In this article, we will explore the latest advancements in CNC router technology, with a specific focus on future trends that are shaping the industry.

One of the key trends in CNC router technology development is the integration of advanced automation features. Modern CNC router machines are increasingly equipped with sophisticated software and sensors that allow for automated tool changes, material handling, and process monitoring. This not only improves productivity and reduces human error but also opens up new possibilities for complex machining tasks that would be difficult or impossible to achieve manually.

Another major trend in CNC router technology is the push towards greater precision and accuracy. Manufacturers are constantly developing new technologies to improve the resolution and repeatability of CNC router machines, allowing for more precise cuts, smoother finishes, and tighter tolerances. This is particularly important in industries such as aerospace, automotive, and medical device manufacturing, where the smallest deviation can have a significant impact on the quality of the final product.

One of the most exciting developments in CNC router technology is the adoption of advanced materials and processes. With the rise of composite materials, 3D printing, and additive manufacturing, CNC router machines are being used to explore new possibilities for cutting, shaping, and finishing a wide range of materials, from traditional woods and metals to exotic composites and even living tissue. This opens up new opportunities for creativity and innovation in fields such as art, design, and architecture.

In addition to these technical advancements, there is also a growing focus on sustainability and environmental responsibility in CNC router technology development. Manufacturers are increasingly incorporating energy-efficient components, recycling programs, and eco-friendly materials into their products, in response to growing consumer demand for sustainable solutions. This includes the use of renewable energy sources, such as solar power, as well as the development of closed-loop systems that minimize waste and pollution.

Overall, the future of CNC router technology is bright, with new innovations and advancements driving the industry forward at an unprecedented pace. By staying ahead of the curve and embracing emerging trends in automation, precision, materials, and sustainability, manufacturers and end-users alike can unlock new levels of productivity, creativity, and profitability in the CNC router machine industry.

Conclusion

In conclusion, the latest advancements in CNC router technology have undoubtedly revolutionized the manufacturing industry. With increased precision, speed, and versatility, these cutting-edge machines have allowed for the creation of intricate designs and prototypes with unparalleled efficiency. As technology continues to evolve, we can only imagine the incredible possibilities that lie ahead for CNC routers. Whether you are a hobbyist or a professional in the field, investing in the latest CNC router technology is sure to elevate your craftsmanship to new heights. Embrace the future of manufacturing with these innovative tools and stay ahead of the curve in this constantly evolving industry.