Unleashing The Potential: The Latest Innovations In CNC Wood Router Machines

Welcome to the future of woodworking with the latest innovations in CNC wood router machines. In this article, we will explore how these cutting-edge technology has revolutionized the woodworking industry, unleashing the full potential of creativity and precision. From intricate designs to flawless finishes, discover how these CNC machines are changing the game for woodworkers everywhere. Join us as we delve into the exciting world of CNC wood router machines and all they have to offer.

- Advancements in CNC Technology for Woodworking

In a rapidly evolving world where technology is constantly changing and advancing, it is no surprise that the field of woodworking is also seeing significant growth and innovation. One of the most exciting developments in this industry is the advent of CNC technology for woodworking, particularly in the form of CNC wood router machines. These machines have revolutionized the way woodworkers create intricate and precise designs, allowing them to unleash their creativity and push the boundaries of what is possible in the world of woodworking.

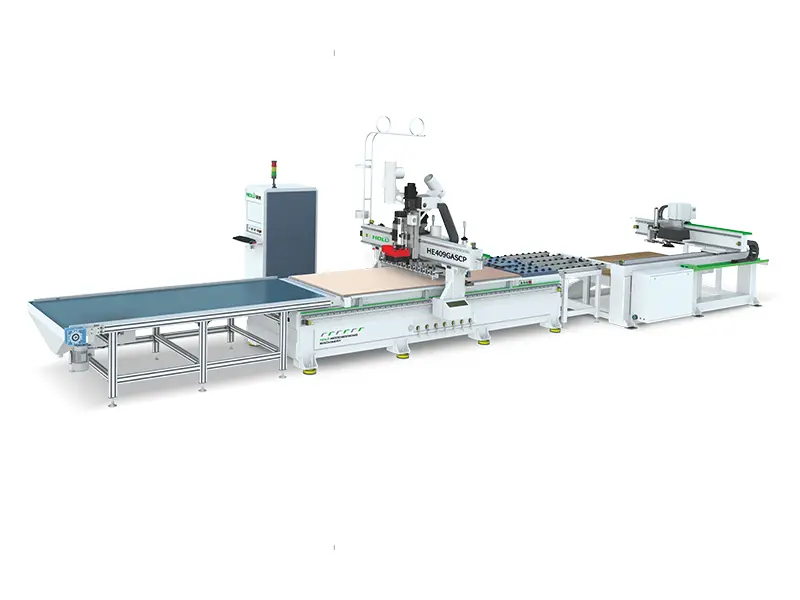

CNC wood router machines are essentially computer-controlled cutting machines that are used to carve out intricate designs and shapes on pieces of wood. These machines are capable of producing high-quality and precise cuts with incredible speed and accuracy, making them an essential tool for any woodworker looking to take their craft to the next level. With advancements in technology, CNC wood router machines have become more sophisticated and user-friendly, making them accessible to woodworkers of all skill levels.

One of the key advancements in CNC technology for woodworking is the integration of CAD (Computer-Aided Design) software. This software allows woodworkers to design their projects digitally, providing them with a virtual prototype of their final product before any cuts are made. This not only saves time and materials but also allows woodworkers to experiment with different designs and patterns without the fear of ruining a piece of wood. With CAD software, the possibilities are endless, and woodworkers can let their imagination run wild, creating intricate and complex designs that were previously unattainable.

Another advancement in CNC wood router machines is the incorporation of high-speed spindles and advanced cutting tools. These tools allow for faster and more precise cuts, resulting in cleaner edges and smoother finishes on the final product. Additionally, the use of advanced cutting tools reduces the wear and tear on the machine, prolonging its lifespan and ensuring that it continues to operate at peak performance for years to come.

In addition to advancements in cutting technology, CNC wood router machines have also seen improvements in their overall design and functionality. Modern machines are equipped with larger work areas, improved dust collection systems, and user-friendly interfaces that make them easier to operate and maintain. These features not only enhance the efficiency of the machine but also make it more convenient for woodworkers to use, saving them time and effort in their projects.

Overall, the latest innovations in CNC wood router machines have truly unleashed the potential of woodworking, allowing woodworkers to create intricate and complex designs with unparalleled precision and speed. With advancements in CAD software, cutting technology, and overall machine design, woodworkers are now able to push the boundaries of their craft and create truly remarkable pieces that were once thought to be impossible. As technology continues to advance, we can only imagine what the future holds for CNC wood router machines and the world of woodworking as a whole.

- Cutting-Edge Features of the Latest CNC Wood Router Machines

In the world of woodworking, CNC wood router machines have revolutionized the way craftsmen and manufacturers create intricate designs and precise cuts on wood. These cutting-edge tools are equipped with advanced features that push the boundaries of what is possible in woodworking. In this article, we will explore the latest innovations in CNC wood router machines, showcasing their potential and highlighting the key features that set them apart from traditional tools.

One of the most important advancements in CNC wood router machines is their ability to produce highly detailed and complex designs with unparalleled precision. These machines are equipped with sophisticated software that allows users to create intricate patterns, intricate carvings, and precise cuts with ease. With the use of computer-aided design (CAD) software, craftsmen can design their projects down to the smallest detail and then watch as the CNC router brings their vision to life.

Another key feature of the latest CNC wood router machines is their speed and efficiency. These machines are capable of completing projects in a fraction of the time it would take using traditional tools. With automatic tool changers, high-speed spindles, and multi-axis control, CNC wood router machines can cut, shape, and carve wood with precision and speed. This not only increases productivity but also allows craftsmen to take on more complex projects and deliver them in a timely manner.

In addition to their speed and precision, CNC wood router machines offer versatility in terms of the materials they can work with. While wood is the primary material for these machines, they can also cut and shape other materials such as plastics, composites, and even metals. This opens up a whole new world of possibilities for craftsmen looking to experiment with different materials and create unique designs.

Furthermore, the latest CNC wood router machines are equipped with safety features to protect users and prevent accidents. These machines come with safety guards, emergency stop buttons, and built-in sensors that detect any abnormalities during operation. This ensures a safe working environment for craftsmen and reduces the risk of injuries or damage to the machine.

In conclusion, the latest innovations in CNC wood router machines have unleashed a world of potential for craftsmen and manufacturers alike. With their advanced features, speed, precision, versatility, and safety measures, these machines are revolutionizing the woodworking industry and pushing the boundaries of what is possible in woodworking. Whether you are a seasoned craftsman or a novice looking to explore the world of woodworking, investing in a CNC wood router machine is sure to take your projects to the next level.

- Enhancing Precision and Efficiency in Woodworking with CNC Routers

Unleashing the Potential: The Latest Innovations in CNC Wood Router Machines - Enhancing Precision and Efficiency in Woodworking with CNC Routers

Woodworking has been revolutionized by the advancements in technology, particularly with the introduction of CNC wood router machines. These machines have transformed the way in which wood is shaped and manipulated, allowing for increased precision and efficiency in the woodworking process. In this article, we will explore the latest innovations in CNC wood router machines and how they are enhancing precision and efficiency in woodworking.

One of the key benefits of CNC wood router machines is their ability to precisely cut and shape wood with incredible accuracy. This is achieved through the use of computer-aided design (CAD) software, which allows for intricate designs and patterns to be programmed into the machine. The CNC router then follows these instructions to cut and shape the wood with extreme precision, ensuring that each piece is exactly as specified.

In addition to precision, CNC wood router machines also offer increased efficiency in the woodworking process. Traditional woodworking methods often require a significant amount of time and effort to manually cut and shape wood, but CNC routers are able to complete these tasks much more quickly and easily. This not only saves time, but also allows for greater productivity and output in a shorter amount of time.

One of the latest innovations in CNC wood router machines is the integration of automated tool changers. These tool changers allow the machine to automatically switch between different cutting tools, such as drills, saws, and routers, without the need for manual intervention. This not only saves time and reduces the risk of human error, but also allows for a greater variety of cuts and shapes to be achieved with a single machine.

Another innovation in CNC wood router machines is the use of advanced sensors and cameras to monitor the cutting process in real time. These sensors can detect any discrepancies or errors in the cutting path, allowing for adjustments to be made on the fly to ensure a perfect cut every time. This level of precision and accuracy is not possible with traditional woodworking methods, demonstrating the clear advantage of CNC routers in the woodworking industry.

Overall, CNC wood router machines are revolutionizing the woodworking industry by enhancing precision and efficiency in the woodworking process. With the latest innovations in automated tool changers and real-time monitoring systems, these machines are able to produce intricate designs and shapes with incredible accuracy. As technology continues to advance, we can expect to see even more innovations in CNC wood router machines that further improve the woodworking process.

- Exploring New Possibilities in Design and Production with CNC Machines

In the world of woodworking, CNC wood router machines are revolutionizing the way we design and produce wooden products. These cutting-edge machines are at the forefront of technology, allowing woodworkers to explore new possibilities in design and production. With the ability to precisely carve intricate patterns and shapes into wood, CNC wood router machines are changing the game for craftsmen and manufacturers alike.

One of the key benefits of using a CNC wood router machine is its precision. These machines are capable of creating incredibly detailed designs with unparalleled accuracy. Whether you are looking to create intricate carvings or precise cuts, a CNC wood router machine can help you achieve the exact results you desire. This level of precision opens up a world of possibilities for designers and craftsmen, allowing them to push the boundaries of traditional woodworking techniques.

Another advantage of CNC wood router machines is their efficiency. These machines are able to work quickly and consistently, reducing the time and effort required to produce high-quality wooden products. By automating the cutting and carving process, CNC wood router machines allow woodworkers to increase their productivity and take on more complex projects. This efficiency not only saves time and labor costs but also opens up new opportunities for innovation in the woodworking industry.

In addition to precision and efficiency, CNC wood router machines also offer versatility. These machines can work with a wide range of materials, including hardwoods, softwoods, and even composite materials. This versatility allows designers to experiment with different types of wood and push the boundaries of what is possible in woodworking. Whether you are creating furniture, art pieces, or architectural elements, a CNC wood router machine can help you bring your vision to life with ease.

One of the most exciting innovations in CNC wood router machines is the integration of advanced software and design tools. With these tools, woodworkers can create intricate 3D designs and simulate the cutting process before even touching a piece of wood. This allows designers to experiment with different patterns, textures, and shapes, giving them unprecedented creative freedom. By combining traditional craftsmanship with cutting-edge technology, CNC wood router machines are pushing the boundaries of what is possible in woodworking.

In conclusion, the latest innovations in CNC wood router machines are revolutionizing the woodworking industry. By combining precision, efficiency, versatility, and advanced design tools, these machines are unleashing the potential for designers and craftsmen to explore new possibilities in design and production. Whether you are a seasoned woodworker or a newcomer to the craft, a CNC wood router machine can help you take your projects to the next level. With these cutting-edge machines at your disposal, the possibilities are truly endless in the world of woodworking.

- Maximizing Productivity and Creativity with Innovative CNC Wood Router Technology

In today's fast-paced and highly competitive world of woodworking, staying ahead of the curve is crucial to success. The latest innovations in CNC wood router machines are revolutionizing the way woodworkers approach their craft, offering unparalleled precision, efficiency, and versatility. With a focus on maximizing productivity and creativity, these cutting-edge machines are enabling woodworkers to take their projects to new heights.

One of the key advantages of CNC wood router machines is their ability to consistently produce high-quality cuts with unmatched precision. Unlike traditional woodworking tools, which rely on manual labor and are prone to human error, CNC routers are controlled by computer software, ensuring accuracy down to the smallest detail. This level of precision allows woodworkers to tackle complex designs and intricate patterns with ease, opening up a world of creative possibilities.

In addition to precision, CNC wood router machines also offer unparalleled efficiency. By automating the cutting process, these machines can complete tasks in a fraction of the time it would take using traditional tools. This not only speeds up production times but also allows woodworkers to take on more projects and expand their capabilities. With the ability to quickly switch between different cutting patterns and materials, CNC routers are a versatile tool that can adapt to the changing needs of any project.

Furthermore, the innovative technology behind CNC wood router machines is constantly evolving, with new features and capabilities being introduced regularly. From advanced software that simplifies the design process to state-of-the-art cutting mechanisms that enhance speed and accuracy, woodworkers have access to a wide range of tools that can help them unleash their creative potential. Whether working on custom furniture pieces, intricate carvings, or functional fixtures, CNC routers provide the flexibility and precision needed to bring any project to life.

Overall, the latest innovations in CNC wood router machines are empowering woodworkers to push the boundaries of their craft and unlock new levels of productivity and creativity. By harnessing the power of cutting-edge technology, woodworkers can take on more complex projects, produce higher quality work, and ultimately elevate their craftsmanship to new heights. As the woodworking industry continues to evolve, CNC routers will undoubtedly play a crucial role in shaping the future of this timeless craft.

Conclusion

In conclusion, the latest innovations in CNC wood router machines are truly unleashing their full potential in the woodworking industry. From increased efficiency and precision to enhanced versatility and speed, these advancements are revolutionizing the way woodworkers approach their craft. With features like automatic tool changers, smart sensors, and cloud-based software, these machines are taking woodworking to new heights. As technology continues to evolve, we can only imagine the endless possibilities that lie ahead for CNC wood router machines. So, whether you're a seasoned professional or a DIY enthusiast, investing in these cutting-edge tools will undoubtedly enhance your woodworking experience and enable you to create truly remarkable pieces.