Ultimate Guide To Choosing The Best Computer Panel Saw For Your Woodworking Projects

Are you searching for the perfect computer panel saw to take your woodworking projects to the next level? Look no further! Our comprehensive guide is here to help you navigate the options and choose the best machine for your specific needs. Whether you're a seasoned professional or a DIY enthusiast, this article will provide all the information you need to make an informed decision. Read on to discover the ultimate guide to choosing the best computer panel saw for your woodworking projects.

- Understanding the Different Types of Computer Panel Saws Available

When it comes to woodworking projects, having the right tools is essential to ensuring a successful outcome. One of the most important tools for any woodworker is a computer panel saw. These machines are designed to make precise and accurate cuts in large panels of wood, making them ideal for projects such as cabinets, furniture, and other large-scale woodworking tasks.

There are several different types of computer panel saws available on the market, each with its own unique features and capabilities. In this article, we will explore the different types of computer panel saws available, so you can choose the best one for your woodworking projects.

Vertical Panel Saws

Vertical panel saws are one of the most common types of computer panel saws. They are designed to make vertical cuts in large panels of wood, making them ideal for cutting sheets of plywood or other large materials. Vertical panel saws are typically mounted on a vertical frame, with the cutting blade positioned at the top of the machine. This design allows for easy and precise cuts, making them a popular choice for woodworking shops and production facilities.

Horizontal Panel Saws

Horizontal panel saws are another common type of computer panel saw. Unlike vertical panel saws, horizontal panel saws are designed to make horizontal cuts in large panels of wood. This design makes them ideal for cutting large sheets of plywood or other materials that need to be cut into smaller pieces. Horizontal panel saws are typically mounted on a horizontal frame, with the cutting blade positioned at the side of the machine. This design allows for easy and precise cuts, making them a popular choice for woodworking shops and production facilities.

Sliding Table Panel Saws

Sliding table panel saws are another popular type of computer panel saw. These machines feature a sliding table that allows the user to move the workpiece through the cutting blade, making it easier to make precise and accurate cuts. Sliding table panel saws are ideal for cutting large panels of wood or other materials that need to be cut into smaller pieces. They are also great for cutting angles or bevels in the material, making them a versatile option for woodworking projects.

CNC Panel Saws

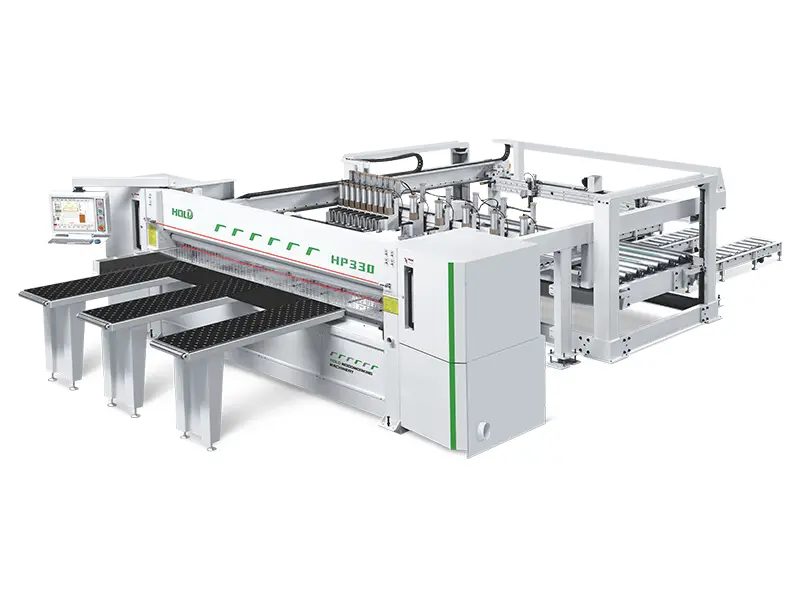

CNC panel saws are the most advanced type of computer panel saw available. These machines are equipped with computer numerical control (CNC) technology, which allows for precise and automated cuts to be made in the material. CNC panel saws are ideal for high-volume production facilities or for woodworkers who need to make complex cuts in their projects. With a CNC panel saw, you can program the machine to make specific cuts, angles, or bevels in the material, ensuring a precise and accurate result every time.

In conclusion, choosing the best computer panel saw for your woodworking projects is essential to achieving success. By understanding the different types of computer panel saws available, you can choose the machine that best fits your needs and budget. Whether you opt for a vertical panel saw, horizontal panel saw, sliding table panel saw, or CNC panel saw, you can be sure that you will have the right tool for the job.

- Key Factors to Consider When Choosing a Computer Panel Saw

When it comes to selecting the right computer panel saw for your woodworking projects, there are several key factors to consider in order to make an informed decision. A computer panel saw is a crucial tool for any woodworker, as it helps to increase efficiency, accuracy, and precision in cutting large panels or sheets of wood. By understanding the important factors to weigh when choosing a computer panel saw, you can ensure that you select the best option for your specific needs and requirements.

One of the first factors to consider when choosing a computer panel saw is the cutting capacity of the machine. This refers to the maximum size of the panels or sheets of wood that the saw can effectively cut. It is important to take into account the size of the materials you typically work with in order to ensure that the saw can accommodate them. Additionally, consider the thickness of the materials the saw can handle, as this will impact the types of projects you can take on.

Another crucial factor to consider is the accuracy and precision of the saw. A computer panel saw should be able to make clean, precise cuts consistently in order to produce high-quality results. Look for saws with advanced digital controls and measurement systems that allow for accurate and repeatable cuts. Additionally, consider the stability and rigidity of the saw’s frame, as this will impact the overall precision of the cuts.

The power and speed of the saw are also important factors to consider. A powerful motor and high cutting speed can help to improve efficiency and productivity, especially when working with large volumes of material. However, it is also important to strike a balance between power and control, as overly powerful saws can sometimes be difficult to handle, particularly for less experienced woodworkers.

Durability and reliability are key considerations when choosing a computer panel saw. Look for saws made from high-quality materials that are built to last. Additionally, consider the reputation of the manufacturer and read reviews from other users to get a sense of the overall reliability of the machine. A reliable saw will not only provide consistent performance but will also require less maintenance and repair over time.

Finally, consider the features and options available on the saw. Some computer panel saws come equipped with additional features such as automatic blade positioning, laser guides, and dust collection systems, which can enhance usability and convenience. Think about which features are most important to you and your woodworking projects, and choose a saw that offers the right combination of functionality and versatility.

In conclusion, choosing the best computer panel saw for your woodworking projects requires careful consideration of various factors, including cutting capacity, accuracy, power, durability, and features. By taking the time to research and evaluate different options, you can select a saw that meets your specific needs and helps you achieve professional-quality results in your woodworking projects.

- Comparing Features and Specs of Top Computer Panel Saw Brands

In the world of woodworking, a computer panel saw is an essential tool for cutting large sheets of material with precision and efficiency. With so many options available on the market, it can be overwhelming to choose the best one for your woodworking projects. This ultimate guide will provide a detailed comparison of features and specs of top computer panel saw brands to help you make an informed decision.

When it comes to choosing a computer panel saw, there are several key factors to consider. The first thing to look at is the cutting capacity of the saw. This refers to the maximum size of material that the saw can accommodate. Some saws are designed for smaller sheets, while others can handle larger panels. Make sure to choose a saw that meets the size requirements of your projects.

Another important factor to consider is the power of the saw. Higher horsepower saws can cut through material more quickly and efficiently, making them ideal for cutting thicker or tougher materials. However, higher power also means higher energy consumption, so consider your power needs before making a decision.

In addition to cutting capacity and power, it’s also important to consider the accuracy and precision of the saw. Look for features such as laser guides or digital readouts that can help you make more precise cuts. Some saws also come with automated features that can improve accuracy and efficiency, such as automatic blade positioning or material feed systems.

When comparing different brands of computer panel saws, it’s important to look at the overall build quality and durability of the saw. Look for a saw that is made from high-quality materials and features a sturdy construction that can withstand the rigors of daily use. It’s also a good idea to read reviews from other users to get an idea of the reliability and longevity of the saw.

Some top computer panel saw brands to consider include Altendorf, Striebig, and SCM. Altendorf is known for its precision and reliability, with saws that are designed for heavy-duty use in professional woodworking shops. Striebig is another popular brand that is known for its vertical panel saws, which are ideal for cutting large sheets of material in a small footprint. SCM is a well-known Italian brand that offers a wide range of panel saws to suit different needs and budgets.

In conclusion, choosing the best computer panel saw for your woodworking projects is a crucial decision that requires careful consideration of features and specs. By comparing top brands and considering factors such as cutting capacity, power, accuracy, and build quality, you can find a saw that meets your needs and helps you achieve precision cuts in your woodworking projects.

- Exploring Advanced Technology and Automation in Computer Panel Saws

In today’s rapidly evolving woodworking industry, technology and automation have become integral components in enhancing efficiency and precision. Computer panel saws, also known as CNC panel saws, have revolutionized the way woodworkers approach cutting and shaping wood materials. This ultimate guide will delve into the advanced technology and automation features that make computer panel saws a valuable asset for woodworking projects.

Computer panel saws are equipped with sophisticated software and precision machinery that allow for highly accurate and efficient cutting of wood panels. By utilizing computer numerical control (CNC) technology, these machines can perform complex cutting tasks with minimal human intervention. This results in a higher level of precision and consistency in cutting, thereby reducing waste and increasing productivity.

One of the key features of computer panel saws is their ability to automatically adjust cutting parameters based on the specific requirements of each project. This not only saves time but also ensures that each cut is made with precision and accuracy. Additionally, computer panel saws can store multiple cutting programs, allowing woodworkers to switch between different projects with ease.

Another important aspect of computer panel saws is their advanced safety features. These machines are equipped with sensors and safety mechanisms that help prevent accidents and injuries during operation. For example, some computer panel saws are equipped with laser sensors that detect any obstacles in the cutting path and automatically stop the machine to prevent collisions.

In addition to their technological advancements, computer panel saws also offer a wide range of automation features that streamline the woodworking process. For instance, some machines come with automatic loading and unloading systems, allowing for continuous operation without the need for manual intervention. This not only saves time but also reduces the risk of human error.

Moreover, computer panel saws can be integrated with other woodworking machinery and software, further enhancing their efficiency and versatility. By connecting these machines to a network, woodworkers can transfer cutting programs seamlessly and monitor the production process in real-time. This level of connectivity enables a more streamlined workflow and greater control over the manufacturing process.

In conclusion, computer panel saws are essential tools for modern woodworkers looking to increase efficiency and precision in their woodworking projects. With their advanced technology and automation features, these machines offer unmatched capabilities for cutting and shaping wood materials. By investing in a high-quality computer panel saw, woodworkers can take their craftsmanship to the next level and achieve superior results in their projects.

- Tips for Maintaining and Maximizing the Performance of Your Computer Panel Saw

Computer panel saws are an essential tool for any woodworking enthusiast or professional. These powerful machines have revolutionized the woodworking industry by offering precision and efficiency in cutting wood panels. However, in order to ensure that your computer panel saw performs at its best and lasts for a long time, it is important to properly maintain and maximize its performance. In this article, we will provide valuable tips on how to do just that.

First and foremost, it is crucial to regularly clean and lubricate your computer panel saw. Dust and debris can accumulate on the saw blades and components, leading to decreased performance and potential damage. Make sure to remove any sawdust and dirt from the machine after each use, and regularly apply lubricant to the moving parts to ensure smooth operation.

In addition to regular cleaning and lubrication, it is important to properly calibrate your computer panel saw. Calibration ensures that the saw blades are aligned correctly and cutting at the right angles, resulting in precise and accurate cuts. Refer to the manufacturer's instructions for guidance on how to calibrate your specific model of computer panel saw.

Another important tip for maintaining and maximizing the performance of your computer panel saw is to check the blade tension regularly. A loose or improperly tensioned blade can lead to inaccurate cuts and potential safety hazards. Make sure to adjust the blade tension according to the manufacturer's recommendations, and replace the blade if it is worn or damaged.

Furthermore, it is crucial to use the right type of blades for your woodworking projects. Different materials and cutting techniques require specific blade types and sizes. Make sure to choose the appropriate blade for each project to ensure optimal performance and quality of the cuts.

When using your computer panel saw, it is also important to follow safety guidelines and practices. Always wear appropriate safety gear, such as goggles and gloves, and never operate the saw without proper training and supervision. Additionally, make sure to keep your work area clean and organized to prevent accidents and injuries.

Lastly, investing in regular maintenance and servicing of your computer panel saw can help prolong its lifespan and maximize its performance. Consider hiring a professional technician to inspect and tune up your machine on a regular basis to ensure that it is operating at its best.

In conclusion, by following these tips for maintaining and maximizing the performance of your computer panel saw, you can enjoy precise and efficient cutting for all your woodworking projects. Remember to clean, lubricate, calibrate, and use the right blades for each project, and always prioritize safety when using your saw. With proper maintenance and care, your computer panel saw can continue to be a valuable tool in your woodworking arsenal.

Conclusion

In conclusion, choosing the best computer panel saw for your woodworking projects is a crucial decision that can greatly impact the quality and efficiency of your work. By considering factors such as cutting capacity, accuracy, safety features, and ease of use, you can ensure that you select a machine that meets your specific needs and budget. With the right panel saw in your workshop, you can take your woodworking projects to the next level and achieve professional results every time. Happy woodworking!