The Ultimate Guide To Finding The Best CNC Router For Your Needs

Are you looking to take your woodworking, metalworking, or crafting projects to the next level? Look no further than our comprehensive guide to finding the best CNC router for your unique needs. Whether you’re a hobbyist or a professional, this article will help you navigate the myriad options available to choose the perfect machine for your workshop. Read on to discover the key factors to consider, expert tips, and top recommendations to ensure you make an informed decision for your CNC routing needs.

- Introduction to CNC Routers: What You Need to Know

to CNC Routers: What You Need to Know

CNC routers have revolutionized the world of woodworking and manufacturing, allowing for precision and efficiency that was previously impossible. If you are in the market for a CNC router, it is important to understand what to look for and what factors to consider in order to find the best machine for your needs.

What is a CNC Router?

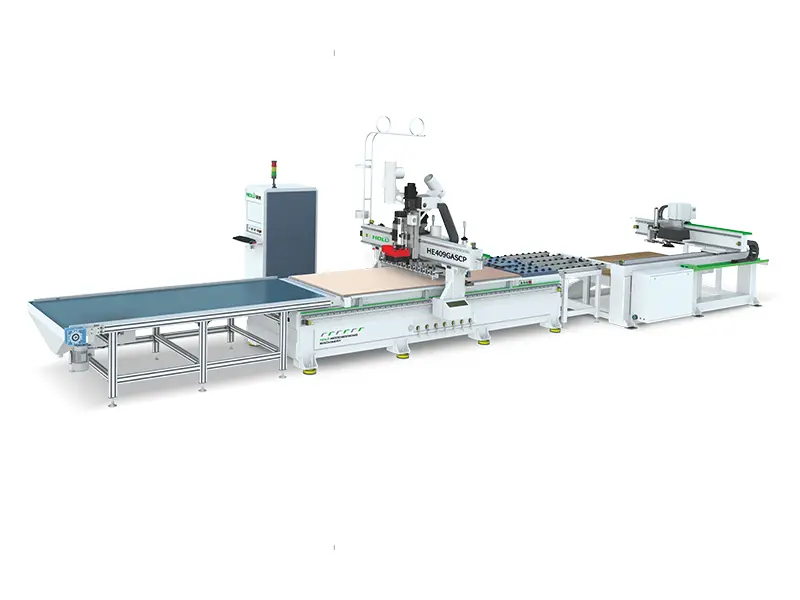

A CNC router is a computer-controlled cutting machine that utilizes a rotating cutter to carve out designs from a wide range of materials, such as wood, plastic, and metal. These machines are used in a variety of industries, from woodworking and cabinetry to sign making and prototyping.

Key Features to Consider

When looking for the best CNC router for your needs, there are several key features to consider:

1. Size: The size of the bed or work area of the CNC router will determine the size of the projects you can tackle. Make sure to choose a machine with a bed size that is suitable for your needs.

2. Power and Speed: Consider the power and speed of the router's spindle motor, as this will affect the machine's cutting capabilities. A higher power motor will allow for faster cutting speeds and the ability to work with tougher materials.

3. Accuracy and Precision: Look for a CNC router that offers high levels of accuracy and precision, measured in terms of repeatability and resolution. This will ensure that your cuts are clean and precise every time.

4. Control System: The control system of the CNC router, often referred to as the CNC controller, is the brain of the machine. Make sure to choose a machine with a user-friendly control system that is easy to operate and offers the features you need.

5. Software Compatibility: Consider the compatibility of the CNC router with the design software you plan to use. Some machines are compatible with a wide range of software programs, while others may be more limited in terms of compatibility.

6. Price: Finally, consider your budget when choosing a CNC router. While it may be tempting to opt for the cheapest option, investing in a higher-quality machine may save you money in the long run by offering better performance and durability.

Finding the Best CNC Router

When it comes to finding the best CNC router for your needs, it is important to do your research and compare different models based on the key features outlined above. Consider reaching out to a professional in the industry for recommendations or reading reviews from other users to get a better idea of what to expect from a particular machine.

Ultimately, the best CNC router for your needs will be one that offers the right balance of size, power, accuracy, and price to suit your specific requirements. By taking the time to consider these factors and compare different options, you can find a machine that will help you take your woodworking or manufacturing projects to the next level.

- Determining Your Requirements: Factors to Consider When Choosing a CNC Router

When it comes to finding the best CNC router for your needs, there are a variety of factors to consider. One of the first steps in the process is determining your requirements. This involves assessing your specific needs and preferences in order to ensure that you choose a machine that is best suited to your individual situation.

One of the most important factors to consider when choosing a CNC router is the size of the machine. The size of the machine will be determined by the size of the projects you plan to undertake. If you will primarily be working on small projects, a compact CNC router may be sufficient. However, if you plan to work on larger projects, you will need a larger machine with a greater cutting area.

Additionally, it is important to consider the type of materials you will be working with. Different CNC routers are designed to handle different materials, so it is important to choose a machine that is capable of cutting the materials you plan to use. For example, if you will be working with wood, you will need a CNC router that is designed specifically for wood cutting.

Another important factor to consider when choosing a CNC router is the level of precision you require. Some CNC routers are capable of very high levels of precision, while others may be more suitable for less precise work. If you require a high level of precision, it is important to choose a machine that is capable of delivering the accuracy you need.

In addition to size, material compatibility, and precision, it is also important to consider the speed and power of the CNC router. The speed of the machine will determine how quickly you can complete your projects, while the power of the machine will determine the types of materials it can handle. It is important to choose a machine that offers the right balance of speed and power for your needs.

Finally, it is important to consider the cost of the CNC router. CNC routers can vary widely in price, so it is important to choose a machine that fits within your budget. It is also important to consider the long-term costs of owning a CNC router, such as maintenance and repair costs.

Overall, choosing the best CNC router for your needs involves carefully assessing your requirements and preferences in order to make an informed decision. By considering factors such as size, material compatibility, precision, speed, power, and cost, you can find a machine that is perfectly suited to your individual situation. With the right CNC router, you can take your woodworking projects to the next level and achieve professional-quality results.

- Researching the Market: Comparing CNC Router Options Available

The Ultimate Guide to Finding the Best CNC Router for Your Needs - Researching the Market: Comparing CNC Router Options Available

When it comes to finding the best CNC router for your needs, thorough market research is a crucial step. With so many options available in the market, comparing different CNC router options will help you make an informed decision and choose the one that suits your requirements perfectly. In this article, we will guide you through the process of researching the market and comparing CNC router options.

Firstly, it is essential to understand why market research is necessary in finding the best CNC router. Investing in a CNC router is a significant financial decision, and selecting the wrong one can lead to wasted time, resources, and money. Therefore, it is essential to have a thorough understanding of the market to ensure you make the right choice.

To begin your research, start by identifying your specific needs and requirements. Consider the level of precision, speed, and size of projects you will be working on. Understanding your specific requirements will help narrow down your options and make it easier to compare different CNC router options.

Once you have a clear idea of your needs, start researching the market for CNC routers that fulfill those requirements. There are various sources to gather information, including online platforms, industry publications, forums, and expert opinions. Take advantage of these resources to gain insights into different CNC router brands, models, and their features.

One important aspect to consider while comparing CNC router options is the machine's build quality. A CNC router with a robust and durable construction will ensure long-term reliability and precision. Look for machines made from high-quality materials like steel or aluminum.

Another essential factor to compare in CNC router options is their cutting capabilities. Different routers have varying maximum cutting depths, speeds, and accuracy levels. Assess your project requirements and compare the capabilities of different routers to find the one that matches your needs.

Additionally, pay attention to the software compatibility of the CNC routers you are considering. The software is a critical component of any CNC router, as it determines the machine's functionality and ease of use. Ensure that the router you choose is compatible with the software you plan to work with or offers its own user-friendly software.

Furthermore, consider the after-sales support and warranty offered by the CNC router manufacturers. A reputable company will provide excellent customer service, technical support, and a warranty on their machines. This is crucial in case you encounter any issues or require assistance in the future.

Price is another factor that needs careful consideration when comparing CNC router options. While it is tempting to opt for the cheapest option, it is important to strike a balance between quality and affordability. Choose a CNC router that provides the best value for your investment and meets your specific needs.

Finally, before making a final decision, read reviews and testimonials from other users who have hands-on experience with the CNC router models you are considering. This will give you valuable insights into their performance, reliability, and user satisfaction.

In conclusion, researching the market and comparing CNC router options is crucial in finding the best CNC router for your needs. Consider your specific requirements, analyze the build quality, cutting capabilities, software compatibility, after-sales support, and price of different routers. By following these steps and gathering information from reliable sources, you can make an informed decision and invest in a CNC router that will meet your expectations and deliver excellent results.

- Making the Right Decision: Selecting the Best CNC Router for Your Specific Needs

In today's rapidly evolving manufacturing industry, investing in the right CNC router is essential for businesses looking to optimize their production processes and stay ahead of the competition. With countless options available on the market, selecting the best CNC router for your specific needs can be a daunting task. However, with the right knowledge and guidance, you can make an informed decision that will positively impact your bottom line.

When it comes to choosing the best CNC router, one of the key factors to consider is the size and capacity of the machine. The size of the CNC router will largely depend on the size of the materials you will be working with and the scale of your production runs. For smaller workshops or hobbyists, a compact desktop CNC router may be sufficient, while larger industrial operations may require a full-sized CNC router with a larger cutting area. It is crucial to carefully assess your production needs and choose a machine that can handle the workload efficiently.

Another important consideration when selecting the best CNC router is the type of materials you will be working with. Different CNC routers are designed to cut and carve different materials, from wood and plastic to metal and composites. It is essential to choose a machine that is capable of processing the materials you work with regularly to ensure optimal performance and longevity of the equipment.

In addition to size and material compatibility, you should also consider the accuracy and precision of the CNC router. The best CNC routers offer high levels of accuracy and repeatability, allowing for consistent and precise cuts every time. Look for machines with advanced features such as servo motors, linear guides, and high-resolution spindles to ensure superior cutting quality and efficiency.

When evaluating different CNC router options, it is also important to consider the machine's speed and performance capabilities. A fast and reliable CNC router can significantly increase productivity and reduce production times, ultimately saving you time and money. Look for machines with high-speed machining capabilities and rapid tool change systems to maximize efficiency and output.

Finally, consider the overall compatibility and ease of use of the CNC router. The best CNC routers are equipped with user-friendly interfaces and intuitive software that make programming and operation straightforward and efficient. Additionally, look for machines that are compatible with industry-standard CAD/CAM software programs to streamline the design and production process.

In conclusion, finding the best CNC router for your specific needs requires careful consideration of factors such as size, material compatibility, precision, speed, and usability. By taking the time to assess your production requirements and research different machine options, you can make an informed decision that will enhance your production capabilities and set your business up for success in the ever-evolving manufacturing landscape.

- Getting Started: Setting Up and Using Your New CNC Router Efficiently

Whether you are a seasoned professional or a beginner in the world of woodworking, finding the best CNC router for your needs is crucial to achieving efficient and precise results. In this comprehensive guide, we will walk you through the process of setting up and using your new CNC router effectively.

Setting up your CNC router is the first step in maximizing its potential. Before you even unpack your machine, it is important to carefully read the manufacturer's instructions and familiarize yourself with all the components. This will ensure that you assemble the machine correctly and avoid any potential issues down the line.

Once your CNC router is fully assembled, the next step is to calibrate it for optimal performance. This includes adjusting the machine's settings such as speed, depth of cut, and tool paths to suit the specific requirements of your project. It is also important to test the machine on a scrap piece of material to ensure that everything is running smoothly before starting on your actual project.

When it comes to using your CNC router efficiently, there are a few key tips to keep in mind. Firstly, always use the appropriate tool for the job and make sure that it is properly secured in the spindle. Additionally, take the time to properly fix your material in place to avoid any movement during the cutting process. This will help to ensure accurate and precise results.

In order to get the most out of your CNC router, it is important to regularly maintain and clean the machine. This includes cleaning the cutting area and removing any debris that may have built up during use. It is also important to regularly check and lubricate the moving parts of the machine to prevent any wear and tear.

In conclusion, finding the best CNC router for your needs is a crucial step in achieving efficient and precise results in your woodworking projects. By following the tips outlined in this guide and taking the time to properly set up and maintain your machine, you can ensure that you are getting the most out of your investment. So, what are you waiting for? Get started on your woodworking journey with your new CNC router today!

Conclusion

In conclusion, choosing the best CNC router for your needs is a crucial decision that should not be taken lightly. By following the tips and guidelines outlined in this ultimate guide, you can make an informed decision that meets your specific requirements and budget. Remember to consider factors such as machine size, cutting capabilities, software compatibility, and customer support when researching and comparing CNC routers. Investing in the right CNC router will not only improve the quality and efficiency of your projects, but also save you time and money in the long run. With the right machine by your side, the possibilities for creating precision designs and prototypes are endless. So, take the time to do your research and find the best CNC router that will help you bring your ideas to life. Happy cutting!